Page 238 - Basic Principles of Textile Coloration

P. 238

MACHINES FOR DYEING FABRIC 227

roller may also have a lower temperature unless the roller is wrapped to minimise

heat transfer to the metal. It is usual to add only half the dye solution at the

beginning of the first end, the rest being added before the second. Before dyeing

begins, an end cloth may be passed back and forth through the heated bath to

heat up the draw roller. Listing can arise from non-uniform temperature across the

width of the fabric, or from non-uniform pressure that squeezes the retained dye

liquor across the fabric width between the layers. After dyeing, the roll of fabric

slowly turns to avoid drainage of dye liquor into the lower layers of fabric. Moiré

effects or water marks may arise on some acetate and nylon fabrics because of

pressure flattening the structure of the rolled fabric. Larger diameter rollers, and a

soft end cloth, avoid this.

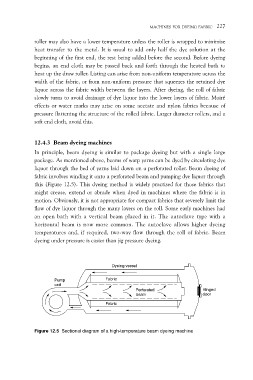

12.4.3 Beam dyeing machines

In principle, beam dyeing is similar to package dyeing but with a single large

package. As mentioned above, beams of warp yarns can be dyed by circulating dye

liquor through the bed of yarns laid down on a perforated roller. Beam dyeing of

fabric involves winding it onto a perforated beam and pumping dye liquor through

this (Figure 12.5). This dyeing method is widely practised for those fabrics that

might crease, extend or abrade when dyed in machines where the fabric is in

motion. Obviously, it is not appropriate for compact fabrics that severely limit the

flow of dye liquor through the many layers on the roll. Some early machines had

an open bath with a vertical beam placed in it. The autoclave type with a

horizontal beam is now more common. The autoclave allows higher dyeing

temperatures and, if required, two-way flow through the roll of fabric. Beam

dyeing under pressure is easier than jig pressure dyeing.

Dyeing vessel

Pump Fabric

unit Fabric

Perforated Hinged

beam door

Figure 12.5 Sectional diagram of a high-temperature beam dyeing machine