Page 57 - E BOOK ENGINE MECHANICAL M2

P. 57

3. FUEL SYSTEM

3. COMMON RAIL

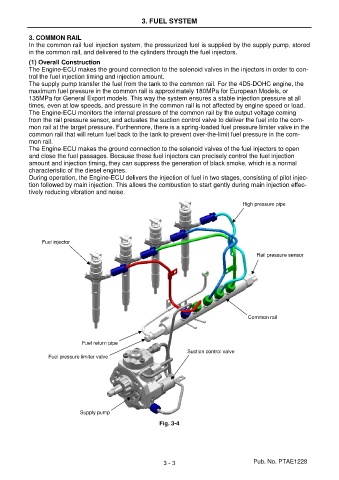

In the common rail fuel injection system, the pressurized fuel is supplied by the supply pump, stored

in the common rail, and delivered to the cylinders through the fuel injectors.

(1) Overall Construction

The Engine-ECU makes the ground connection to the solenoid valves in the injectors in order to con-

trol the fuel injection timing and injection amount.

The supply pump transfer the fuel from the tank to the common rail. For the 4D5-DOHC engine, the

maximum fuel pressure in the common rail is approximately 180MPa for European Models, or

135MPa for General Export models. This way the system ensures a stable injection pressure at all

times, even at low speeds, and pressure in the common rail is not affected by engine speed or load.

The Engine-ECU monitors the internal pressure of the common rail by the output voltage coming

from the rail pressure sensor, and actuates the suction control valve to deliver the fuel into the com-

mon rail at the target pressure. Furthermore, there is a spring-loaded fuel pressure limiter valve in the

common rail that will return fuel back to the tank to prevent over-the-limit fuel pressure in the com-

mon rail.

The Engine-ECU makes the ground connection to the solenoid valves of the fuel injectors to open

and close the fuel passages. Because these fuel injectors can precisely control the fuel injection

amount and injection timing, they can suppress the generation of black smoke, which is a normal

characteristic of the diesel engines.

During operation, the Engine-ECU delivers the injection of fuel in two stages, consisting of pilot injec-

tion followed by main injection. This allows the combustion to start gently during main injection effec-

tively reducing vibration and noise.

High pressure pipe

Fuel injector

Rail pressure sensor

Common rail

Fuel return pipe

Suction control valve

Fuel pressure limiter valve

Supply pump

Fig. 3-4

3 - 3 Pub. No. PTAE1228