Page 55 - E BOOK ENGINE MECHANICAL M2

P. 55

3. FUEL SYSTEM

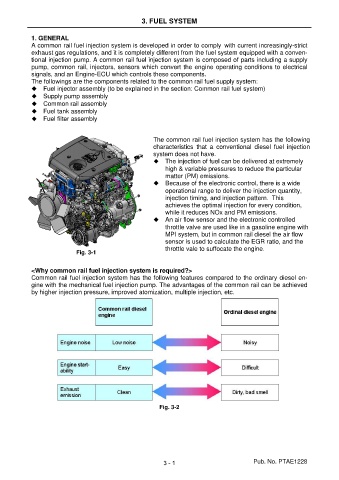

1. GENERAL

A common rail fuel injection system is developed in order to comply with current increasingly-strict

exhaust gas regulations, and it is completely different from the fuel system equipped with a conven-

tional injection pump. A common rail fuel injection system is composed of parts including a supply

pump, common rail, injectors, sensors which convert the engine operating conditions to electrical

signals, and an Engine-ECU which controls these components.

The followings are the components related to the common rail fuel supply system:

◆ Fuel injector assembly (to be explained in the section: Common rail fuel system)

◆ Supply pump assembly

◆ Common rail assembly

◆ Fuel tank assembly

◆ Fuel filter assembly

The common rail fuel injection system has the following

characteristics that a conventional diesel fuel injection

system does not have.

◆ The injection of fuel can be delivered at extremely

high & variable pressures to reduce the particular

matter (PM) emissions.

◆ Because of the electronic control, there is a wide

operational range to deliver the injection quantity,

injection timing, and injection pattern. This

achieves the optimal injection for every condition,

while it reduces NOx and PM emissions.

◆ An air flow sensor and the electronic controlled

throttle valve are used like in a gasoline engine with

MPI system, but in common rail diesel the air flow

sensor is used to calculate the EGR ratio, and the

Fig. 3-1 throttle vale to suffocate the engine.

<Why common rail fuel injection system is required?>

Common rail fuel injection system has the following features compared to the ordinary diesel en-

gine with the mechanical fuel injection pump. The advantages of the common rail can be achieved

by higher injection pressure, improved atomization, multiple injection, etc.

Fig. 3-2

3 - 1 Pub. No. PTAE1228