Page 45 - Unit2.docx

P. 45

specified load acting on the head of the pile

© It's Engg. Life

SINGLE PILE DESIGN

5.2 End bearing piles

If a pile is installed in a soil with low bearing capacity but resting on soil beneath

with high bearing capacity, most of the load is carried by the end bearing.

In some cases where piles are driven in to the ground using hammer, pile

capacity can be estimated by calculating the transfer of potential energy into

dynamic energy . When the hammer is lifted and thrown down, with some energy

lose while driving the pile, potential energy is transferred into dynamic energy. In

the final stage of the pile’s embedment,On the bases of rate of settlement, it is

able to calculate the design capacity of the pile.

For standard pile driving hammers and some standard piles with load capacity

(F Rsp, ), the working load for the pile can be determined using the relationship

between bearing capacity of the pile, the design load capacity of the pile

described by: F Rsp ≥ γ F Sd and table 5-2

n⋅

where: F Sd = design load for end baring.

The data is valid only if at the final stage, rate of settlement is 20 mm per ten

blow. And pile length not more than 20 m and geo-category 2 . for piles with

length 20 - 30 m respective 30 - 50 m the bearing capacity should be reduced by

20 res. 25%.

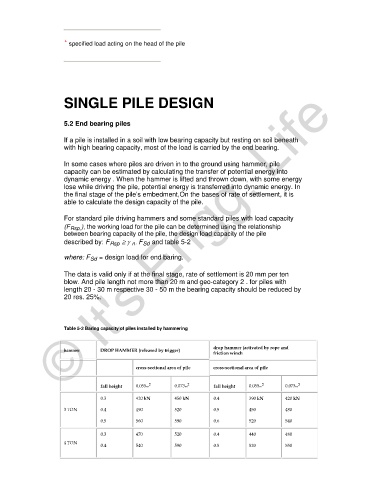

Table 5-2 Baring capacity of piles installed by hammering

hammer DROP HAMMER (released by trigger) drop hammer (activated by rope and

friction winch

cross-sectional area of pile cross-sectional area of pile

fall height 0.055m 2 0.073m 2 fall height 0.055m 2 0.073m 2

0.3 420 kN 450 kN 0.4 390 kN 420 kN

3 TON 0.4 490 520 0.5 450 480

0.5 560 590 0.6 520 540

0.3 470 520 0.4 440 480

4 TON 0.4 540 590 0.5 520 550