Page 50 - Unit2.docx

P. 50

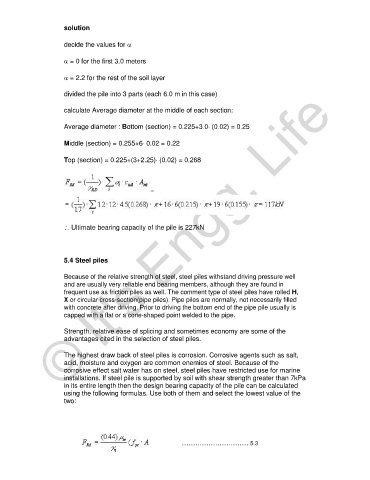

solution

decide the values for α

α = 0 for the first 3.0 meters

α = 2.2 for the rest of the soil layer

divided the pile into 3 parts (each 6.0 m in this case)

calculate Average diameter at the middle of each section:

Average diameter : Bottom (section) = 0.225+3.0⋅ (0.02) = 0.25

Middle (section) = 0.255+6⋅ 0.02 = 0.22

Top (section) = 0.225+(3+2.25)⋅ (0.02) = 0.268

=

∴ Ultimate bearing capacity of the pile is 227kN

© It's Engg. Life

5.4 Steel piles

Because of the relative strength of steel, steel piles withstand driving pressure well

and are usually very reliable end bearing members, although they are found in

frequent use as friction piles as well. The comment type of steel piles have rolled H,

X or circular cross-section(pipe piles). Pipe piles are normally, not necessarily filled

with concrete after driving. Prior to driving the bottom end of the pipe pile usually is

capped with a flat or a cone-shaped point welded to the pipe.

Strength, relative ease of splicing and sometimes economy are some of the

advantages cited in the selection of steel piles.

The highest draw back of steel piles is corrosion. Corrosive agents such as salt,

acid, moisture and oxygen are common enemies of steel. Because of the

corrosive effect salt water has on steel, steel piles have restricted use for marine

installations. If steel pile is supported by soil with shear strength greater than 7kPa

in its entire length then the design bearing capacity of the pile can be calculated

using the following formulas. Use both of them and select the lowest value of the

two:

………………………… 5.3