Page 1052 - YG 2019

P. 1052

ALU-POWER ALU-POWER

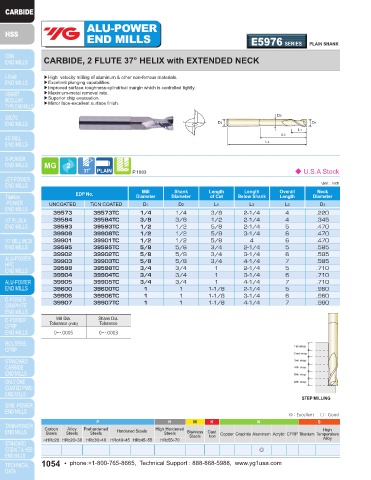

END MILLS E5976 SERIES PLAIN SHANK END MILLS E5980 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE 37° HELIX with EXTENDED NECK CARBIDE, 3 FLUTE 45° HELIX STUB LENGTH

▶High velocity milling of aluminum & other non-ferrous materials. ▶Designed to machine aluminium at high speed condition.

▶Excellent plunging capabilities. ▶Improved surface roughness-cylindrical margin which is controlled tightly.

▶Improved surface roughness-cylindrical margin which is controlled tightly. ▶Mirror face-excellent surface finish.

▶Maximum-metal removal rate.

▶Superior chip evacuation.

▶Mirror face-excellent surface finish.

D3

D2 D1

L1

L3

L2

P.1083 ◆ U.S.A Stock P.1081 ◆ U.S.A Stock

Unit : Inch Unit : Inch

Mill

Mill

Shank

Neck

Shank

Length

EDP No. Diameter Diameter Length Below Shank Overall Diameter UNCOATED EDP No. TiCN COATED Diameter Diameter Length Overall

of Cut

Length

of Cut

Length

UNCOATED TiCN COATED D1 D2 L1 L3 L2 D3 25558 25558TC 1/8 1/8 1/4 1-1/2

39573 39573TC 1/4 1/4 3/8 2-1/4 4 .220 25565 25565TC 3/16 3/16 5/16 2

39584 39584TC 3/8 3/8 1/2 2-1/4 4 .345 25573 25573TC 1/4 1/4 3/8 2

39593 39593TC 1/2 1/2 5/8 2-1/4 5 .470 25579 25579TC 5/16 5/16 7/16 2

39908 39908TC 1/2 1/2 5/8 3-1/4 6 .470 25584 25584TC 3/8 3/8 1/2 2

39901 39901TC 1/2 1/2 5/8 4 6 .470 25588 25588TC 7/16 7/16 9/16 2-1/2

39595 39595TC 5/8 5/8 3/4 2-1/4 5 .585 25593 25593TC 1/2 1/2 5/8 2-1/2

39902 39902TC 5/8 5/8 3/4 3-1/4 6 .585 25595 25595TC 5/8 5/8 3/4 3

39903 39903TC 5/8 5/8 3/4 4-1/4 7 .585 25598 25598TC 3/4 3/4 1 3

39598 39598TC 3/4 3/4 1 2-1/4 5 .710 25600 25600TC 1 1 1-1/4 3

39904 39904TC 3/4 3/4 1 3-1/4 6 .710

39905 39905TC 3/4 3/4 1 4-1/4 7 .710 Mill Dia. Shank Dia.

39600 39600TC 1 1 1-1/8 2-1/4 5 .960 Tolerance (inch) Tolerance

39906 39906TC 1 1 1-1/8 3-1/4 6 .960 0~-.0005 0~-.0003

39907 39907TC 1 1 1-1/8 4-1/4 7 .960

Mill Dia. Shank Dia.

Tolerance (inch) Tolerance

0~-.0005 0~-.0003

• High performance in machining aluminum and CYLINDRICAL MARGIN

non-ferrous materials ECCENTRIC

• Special designed geometry with high rigidity PRIMARY RELIEF

cutting edge

• Improved surface roughness - cylindrical margin

which is controlled tightly.

• Excellent chip removal - higher rake angle, higher CHIP

POCKET

helix angle(45°), bigger chip pocket.

STEP MILLING

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Iron

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

◎ ◎

1054 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1055