Page 1065 - YG 2019

P. 1065

ALU-POWER E5522 SERIES PLAIN SHANK ALU-POWER

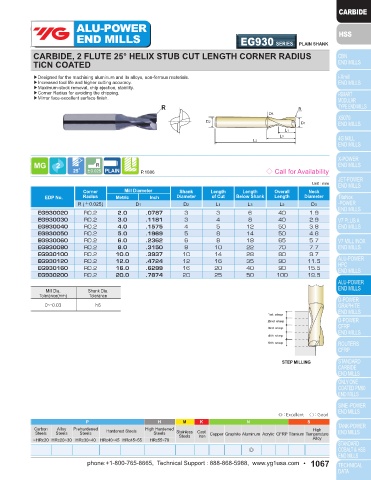

END MILLS EG522 SERIES PLAIN SHANK END MILLS EG930 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE 45° HELIX LONG LENGTH - TiCN COATED CARBIDE, 2 FLUTE 25° HELIX STUB CUT LENGTH CORNER RADIUS

TiCN COATED

▶Suitable for high speed machining in aluminum and other non-ferrous materials, excellent surface finishes, superior chip removal. ▶Designed for the machining aluminum and its alloys, non-ferrous materials.

▶Mirror face-excellent surface finish. ▶Increased tool life and higher cutting accuracy.

▶Maximum-stock removal, chip ejection, stability.

▶Corner Radius for avoiding the chipping.

▶Mirror face-excellent surface finish.

R R

↙

D3

D2 D1

L1

L3

L2

P.1086 ◇ Call for Availability P.1086 ◇ Call for Availability

Unit : mm Unit : mm

EDP No. Mill Diameter Shank Length Overall Corner Mill Diameter Shank Length Length Overall Neck

UNCOATED TiCN COATED Metric Inch Diameter of Cut Length EDP No. Radius Metric Inch Diameter of Cut Below Shank Length Diameter

E5522030 EG522030 3.0 .1181 6 8 57 R (±0.025) D1 D2 L1 L3 L2 D3

E5522040 EG522040 4.0 .1575 6 11 57 EG930020 R0.2 2.0 .0787 3 3 6 40 1.9

E5522050 EG522050 5.0 .1969 6 13 57 EG930030 R0.2 3.0 .1181 3 4 8 40 2.9

E5522060 EG522060 6.0 .2362 6 13 57 EG930040 R0.2 4.0 .1575 4 5 12 50 3.8

E5522080 EG522080 8.0 .3150 8 19 63 EG930050 R0.2 5.0 .1969 5 8 14 50 4.8

E5522100 EG522100 10.0 .3937 10 22 72 EG930060 R0.2 6.0 .2362 6 8 18 65 5.7

E5522120 EG522120 12.0 .4724 12 26 83 EG930080 R0.2 8.0 .3150 8 10 22 70 7.7

E5522140 EG522140 14.0 .5512 14 26 83 EG930100 R0.2 10.0 .3937 10 14 28 80 9.7

E5522160 EG522160 16.0 .6299 16 32 92 EG930120 R0.2 12.0 .4724 12 16 35 90 11.5

E5522180 EG522180 18.0 .7087 18 32 92 EG930160 R0.2 16.0 .6299 16 20 40 90 15.5

E5522200 EG522200 20.0 .7874 20 38 104 EG930200 R0.2 20.0 .7874 20 25 50 100 19.5

Mill Dia. Shank Dia. Mill Dia. Shank Dia.

Tolerance(mm) Tolerance Tolerance(mm) Tolerance

0~-0.03 h6 0~-0.03 h6

Enforced cutting edge

• High performance in machining aluminum and non-ferrous materials CYLINDRICAL MARGIN

• Special designed geometry with high rigidity cutting edge ECCENTRIC

• Improved surface roughness - cylindrical margin which is controlled tightly. PRIMARY RELIEF STEP MILLING

• Excellent chip removal - higher rake angle, higher helix angle(45°), bigger chip pocket.

CHIP

POCKET

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

◎ ◎

1066 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1067