Page 1099 - YG 2019

P. 1099

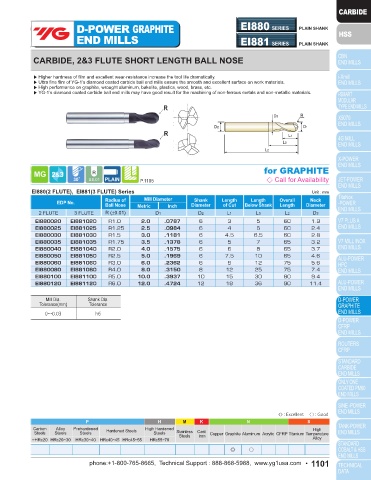

D-POWER GRAPHITE D-POWER GRAPHITE EI880 SERIES PLAIN SHANK

END MILLS EIB06 SERIES PLAIN SHANK END MILLS EI881 SERIES PLAIN SHANK

CARBIDE, 4 FLUTE REGULAR LENGTH CORNER RADIUS with NECK CARBIDE, 2&3 FLUTE SHORT LENGTH BALL NOSE

▶ Higher hardness of film and excellent wear-resistance increase the tool life dramatically. ▶ Higher hardness of film and excellent wear-resistance increase the tool life dramatically.

▶ Ultra fine film of YG-1’s diamond coated carbide ball end mills ensure the smooth and excellent surface on work materials. ▶ Ultra fine film of YG-1’s diamond coated carbide ball end mills ensure the smooth and excellent surface on work materials.

▶ High performance on graphite, wrought aluminum, bakelite, plastics, wood, brass, etc. ▶ High performance on graphite, wrought aluminum, bakelite, plastics, wood, brass, etc.

▶ YG-1’s diamond coated carbide ball end mills may have good result for the machining of non-ferrous metals and non-metallic materials. ▶ YG-1’s diamond coated carbide ball end mills may have good result for the machining of non-ferrous metals and non-metallic materials.

R

↙

R R

↙ D3

D2 D1

L1 R

L3 ↙

L2

for GRAPHITE for GRAPHITE

P.1105 ◆ U.S.A Stock P.1105 ◇ Call for Availability

Unit : Inch EI880(2 FLUTE), EI881(3 FLUTE) Series Unit : mm

Corner Mill Shank Length Length Overall Neck EDP No. Radius of Mill Diameter Shank Length Length Overall Neck

EDP No. Radius Diameter Diameter of Cut Below Shank Length Diameter Ball Nose Metric Inch Diameter of Cut Below Shank Length Diameter

R (±.001) D1 D2 L1 L3 L2 D3 2 FLUTE 3 FLUTE R (±0.01) D1 D2 L1 L3 L2 D3

EIB06002 R.005 1/32 1/8 3/32 3/8 3 .028 EI880020 EI881020 R1.0 2.0 .0787 6 3 5 60 1.9

EIB06901 R.005 1/32 1/8 3/32 1/2 3 .028 EI880025 EI881025 R1.25 2.5 .0984 6 4 6 60 2.4

EIB06003 R.010 3/64 1/8 9/64 9/16 3 .043 EI880030 EI881030 R1.5 3.0 .1181 6 4.5 6.5 60 2.8

EIB06902 R.010 3/64 1/8 9/64 3/4 3 .043 EI880035 EI881035 R1.75 3.5 .1378 6 5 7 65 3.2

EIB06004 R.010 1/16 1/8 3/16 3/4 3 .057 EI880040 EI881040 R2.0 4.0 .1575 6 6 8 65 3.7

EIB06903 R.010 1/16 1/8 3/16 1 3 .057 EI880050 EI881050 R2.5 5.0 .1969 6 7.5 10 65 4.6

EIB06006 R.010 3/32 1/8 9/32 1 3 .086 EI880060 EI881060 R3.0 6.0 .2362 6 9 12 75 5.6

EIB06904 R.010 3/32 1/8 9/32 1-1/2 3 .086 EI880080 EI881080 R4.0 8.0 .3150 8 12 25 75 7.4

EIB06008 R.010 1/8 1/8 3/8 1-1/2 3 .115 EI880100 EI881100 R5.0 10.0 .3937 10 15 30 80 9.4

EIB06905 R.010 1/8 1/8 3/8 2 3 .115 EI880120 EI881120 R6.0 12.0 .4724 12 18 36 90 11.4

EIB06906 R.015 1/8 1/8 3/16 .800 2-1/2 .115

EIB06907 R.020 3/8 3/8 3/8 3 6 .355 Mill Dia. Shank Dia.

Tolerance(mm) Tolerance

Mill Dia. Shank Dia. 0~-0.03 h6

Tolerance(inch) Tolerance

0~-.0012 0~-.0003

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened Hardened Steels High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Steels Iron Alloy

◎ ○ ◎ ○

1100 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1101