Page 1292 - YG 2019

P. 1292

COBALT & HSS

END MILLS RECOMMENDED CUTTING CONDITIONS

END MILLS Being the best through innovation

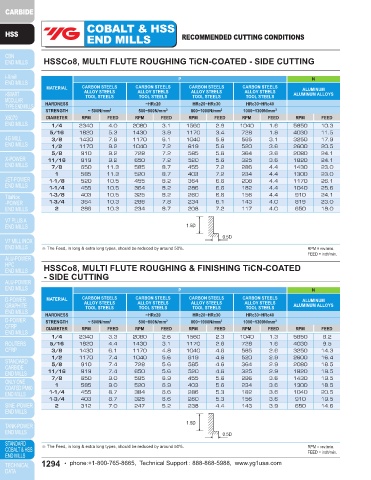

HSSCo8, MULTI FLUTE ROUGHING TiCN-COATED - SIDE CUTTING

P N

MATERIAL CARBON STEELS CARBON STEELS CARBON STEELS CARBON STEELS ALUMINUM

ALLOY STEELS ALLOY STEELS ALLOY STEELS ALLOY STEELS ALUMINUM ALLOYS

TOOL STEELS TOOL STEELS TOOL STEELS TOOL STEELS

HARDNESS ~HRc20 HRc20~HRc30 HRc30~HRc40

STRENGTH ~ 500N/mm 2 500~800N/mm 2 800~1000N/mm 2 1000~1300N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

1/4 2340 4.0 2080 3.1 1560 2.9 1040 1.6 5850 10.3

5/16 1820 5.3 1430 3.9 1170 3.4 728 1.8 4030 11.5

3/8 1430 7.8 1170 6.1 1040 5.6 585 3.1 3250 17.9

1/2 1170 9.2 1040 7.2 819 5.6 520 3.6 2600 20.5

5/8 910 9.2 728 7.2 585 5.6 364 3.6 2080 24.1

11/16 819 9.2 650 7.2 520 5.6 325 3.6 1820 24.1

7/8 650 11.3 585 8.7 455 7.2 286 4.4 1430 23.0

1 585 11.3 520 8.7 403 7.2 234 4.4 1300 23.0

1-1/8 520 10.5 455 8.2 364 6.6 208 4.4 1170 26.1

1-1/4 455 10.5 364 8.2 286 6.6 182 4.4 1040 25.6

1-3/8 403 10.5 325 8.2 260 6.6 156 4.4 910 24.1

1-3/4 364 10.3 286 7.8 234 6.1 143 4.0 819 23.0

2 286 10.3 234 8.7 208 7.2 117 4.0 650 19.0

1.5D

0.5D

※ The Feed, in long & extra long types, should be reduced by around 50%. RPM = rev./min.

FEED = inch/min.

HSSCo8, MULTI FLUTE ROUGHING & FINISHING TiCN-COATED

- SIDE CUTTING

P N

MATERIAL CARBON STEELS CARBON STEELS CARBON STEELS CARBON STEELS ALUMINUM

ALLOY STEELS ALLOY STEELS ALLOY STEELS ALLOY STEELS ALUMINUM ALLOYS

TOOL STEELS TOOL STEELS TOOL STEELS TOOL STEELS

HARDNESS ~HRc20 HRc20~HRc30 HRc30~HRc40

STRENGTH ~ 500N/mm 2 500~800N/mm 2 800~1000N/mm 2 1000~1300N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

1/4 2340 3.3 2080 2.6 1560 2.3 1040 1.3 5850 8.2

5/16 1820 4.4 1430 3.1 1170 2.6 728 1.6 4030 9.5

3/8 1430 6.1 1170 4.8 1040 4.6 585 2.6 3250 14.3

1/2 1170 7.4 1040 5.6 819 4.6 520 2.9 2600 16.4

5/8 910 7.4 728 5.6 585 4.6 364 2.9 2080 18.5

11/16 819 7.4 650 5.6 520 4.6 325 2.9 1820 19.5 TECHNICAL DATA

7/8 650 9.0 585 6.9 455 5.6 286 3.6 1430 19.5

1 585 9.0 520 6.9 403 5.6 234 3.6 1300 18.5

1-1/4 455 8.7 384 6.6 286 5.3 182 3.6 1040 20.5

1-3/4 403 8.7 325 6.6 260 5.3 156 3.6 910 19.5

2 312 7.0 247 5.2 238 4.4 143 3.9 650 14.6

1.5D

0.5D

※ The Feed, in long & extra long types, should be reduced by around 50%. RPM = rev./min.

FEED = inch/min.

1294 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com