Page 1297 - YG 2019

P. 1297

TECHNICAL TECHNICAL

DATA SUPER CUTTING END MILLS DATA SUPER CUTTING END MILLS

SPEED AND FEED CALCULATIONS 7 Resharpening Peripheral Cutting Edge

FOR MILLING CUTTERS AND OTHER ROTATING TOOLS

TO FIND HAVING FORMULA 1 RESHARPENING PERIPHERAL CUTTING EDGE

Surface(or Periphery) Diameter of Tool in milimeters =D

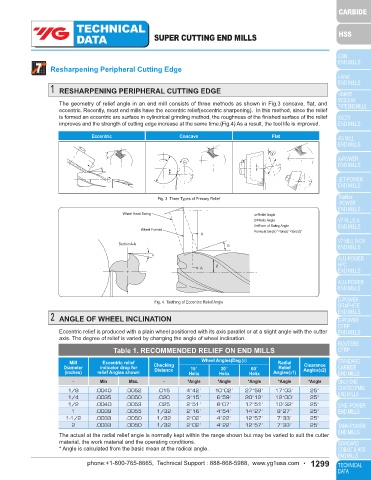

Speed in meter Revolutions per Minute =R.P.M. V= D×3.1416×R.P.M. The geometry of relief angle in an end mill consists of three methods as shown in Fig.3 concave, flat, and

eccentric. Recently, most end mills have the eccentric relief(eccentric sharpening). In this method, since the relief

Per Minute=S.P.M. 1000 is formed an eccentric are surface in cylindrical grinding method, the roughness of the finished surface of the relief

improves and the strength of cutting edge increase at the same time.(Fig.4) As a result, the tool life is improved.

Revolutions Surface Speed in meter per Minute =S.P.M R.P.M.= V×1000

Per Minute=R.P.M. Diameter of Tool in milimeters =D D×3.1416 Eccentric Concave Flat

Feed per Revolution Feed in milimeters per Minute =F.M. F.R.= F.M.

in milimeters-F.R. Revolution per Minute =R.P.M. R.P.M.

Feed in milimeters Feed per Revolution in milimeters =F.R.

Per Minute-F.M. Revolution per Minute =R.P.M. F.M.= F.R.×R.P.M.

Fig. 3. Three Types of Primary Relief

Number of Cutting Teeth Number of Teeth in Tool =T

per Minute=T.M. Revolution per Minute =R.P.M. T.M=T×R.P.M. Wheel Head Swing α=Relief Angle

Ø=Helix Angle

Θ=Form of Swing Angle

Number of Teeth in Tool =T F.R. Wheel Formed A Formula:tan(Θ)°=tan(α)°×tan(Ø)°

Feed per tooth=F.T. F.T.=

Feed per Revolution in milimeters =R.P.M. T

Section A-A

Θ

Number of Teeth in Tool =T α

F.M.

Feed per Tooth=F.T. Feed in milimeters per Minute =F.M. F.T.= T×R.P.M. Ø

Speed in Revolution per Minute =R.P.M. A

5 Case of Resharpening

Fig. 4. Toothing of Eccentric Relief Angle

When the product finish become worse, the cutting edge must get dulled, chips become smaller and the cutting sound gets

louder. In such cases, an end mill must be resharpened. The following are the damages of end mills when the resharpening 2

is required. ANGLE OF WHEEL INCLINATION

Eccentric relief is produced with a plain wheel positioned with its axis parallel or at a slight angle with the cutter

axis. The degree of relief is varied by changing the angle of wheel inclination.

Table 1. RECOMMENDED RELIEF ON END MILLS

Mill Eccentric relief Checking Wheel Angles(Deg.)Θ Radial Clearance

(a) Wear on Primary Relief (b) Wear on Cutting Face (c) Chipping Fig. 1. Damages of Cutting Edge Diameter indicator drop for Distance 15° 30° 60° Relief Angles(α2)

(inches) relief Angles shown Helix Helix Helix Angles(α1)

- Min Max. - *Angle *Angle *Angle *Angle *Angle

6 Sharpen at Predetermined Wear Land 1/8 .0040 .0052 .015 4°42′ 10°02′ 27°58′ 17°03′ 25°

.020

.0050

.0035

1/4

3°15′

20°12′

25°

6°59′

12°00′

1/2 .0040 .0053 .025 2°51′ 6°07′ 17°51′ 10°32′ 25°

Cutters should be sharpened as soon as the wear land(Fig. 2.) reaches a predetermined

width. This width should permit sharpening without excessive loss of tool life. It may 1 .0038 .0055 1/32 2°16′ 4°54′ 14°27′ 8°27′ 25°

vary from a few hundreths to some tenth of a millimeter, depending on the type of cutter 1-1/2 .0033 .0050 1/32 2°02′ 4°22′ 12°57′ 7°33′ 25°

and the finish required on the product. This method is used on production runs where 2 .0033 .0050 1/32 2°02′ 4°22′ 12°57′ 7°33′ 25°

uneven amounts of stock is removed or where the material varies in machinability. It is The actual at the radial relief angle is normally kept within the range shown but may be varied to suit the cutter

also used on small quantity product lots. material, the work material and the operating conditions.

* Angle is calculated from the basic mean at the radical angle.

Fig. 2. Wear Land

1298 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1299