Page 234 - YG 2019

P. 234

STRAIGHT STRAIGHT

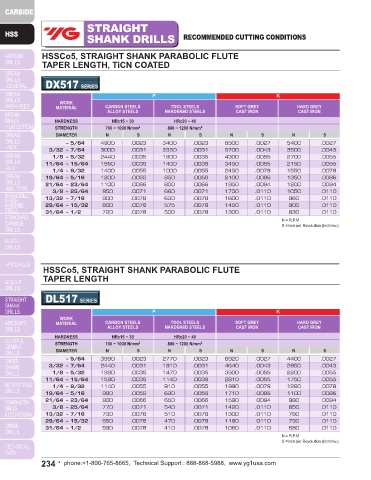

SHANK DRILLS RECOMMENDED CUTTING CONDITIONS SHANK DRILLS RECOMMENDED CUTTING CONDITIONS

HSSCo5, STRAIGHT SHANK PARABOLIC FLUTE

TAPER LENGTH, TiCN COATED HSSCo8, STRAIGHT SHANK DRILL, STUB

DX517 SERIES D4107 SERIES

P K P M

WORK WORK

MATERIAL CARBON STEELS TOOL STEELS SOFT GREY HARD GREY MATERIAL CARBON CARBON CARBON ALLOY STEELS ALLOY STEELS TOOL STEELS STAINLESS

ALLOY STEELS HARDENED STEELS CAST IRON CAST IRON STEELS STEELS STEELS STEELS

HARDNESS HRc15 ~ 30 HRc20 ~ 40 HARDNESS ~ HRc23 ~ HRc23 ~ 28 HRc23 ~ 34 HRc34 ~ 38 HRc23

STRENGTH 700 ~ 1000 N/mm 2 800 ~ 1200 N/mm 2 STRENGTH ~ 570 N/mm 2 ~ 830 N/mm 2 830 ~ 950 N/mm 2 830 ~ 1110 N/mm 2 1110 ~ 1260 N/mm 2 ~ 270 N/mm 2 830 N/mm 2

DIAMETER N S N S N S N S DIAMETER N S N S N S N S N S N S N S

~ 5/64 4900 .0023 3400 .0023 8500 .0027 5400 .0027 2.5 4225 .0010 3200 .0010 2500 .0006 2980 .0008 1750 .0006 3975 .0017 3200 .0010

3/32 ~ 7/64 3000 .0031 2350 .0031 5700 .0043 3500 .0043 3.0 3375 .0020 2500 .0020 2000 .0010 2350 .0020 1375 .0008 3125 .0020 2500 .0020

1/8 ~ 5/32 2440 .0035 1800 .0035 4300 .0055 2700 .0055 5.0 2125 .0025 1600 .0025 1280 .0015 1500 .0025 875 .0010 2000 .0025 1600 .0025

11/64 ~ 15/64 1950 .0039 1400 .0039 3450 .0055 2150 .0055 8.0 1310 .0051 975 .0051 785 .0030 910 .0051 535 .0015 1210 .0051 975 .0051

1/4 ~ 9/32 1400 .0055 1000 .0055 2450 .0078 1550 .0078 11.0 935 .0059 700 .0059 565 .0030 650 .0071 385 .0020 875 .0071 700 .0059

19/64 ~ 5/16 1200 .0059 850 .0059 2100 .0086 1350 .0086 19.0 550 .0091 410 .0091 340 .0051 375 .0091 225 .0020 550 .0091 410 .0091

21/64 ~ 23/64 1100 .0066 800 .0066 1950 .0094 1200 .0094 31.0 325 .0110 244 .0110 193 .0071 225 .0071 134 .0030 300 .0118 244 .0110

3/8 ~ 25/64 950 .0071 660 .0071 1750 .0110 1050 .0110

13/32 ~ 7/16 900 .0078 630 .0078 1600 .0110 960 .0110 K N S

29/64 ~ 15/32 800 .0078 575 .0078 1450 .0110 900 .0110 WORK

31/64 ~ 1/2 720 .0078 500 .0078 1300 .0110 830 .0110 MATERIAL CAST IRON ALUMINUM MAGNESIUM ZINC ALLOYS PLASTIC TITANIUM

ALLOYS ALLOYS ALLOYS

N = R.P.M

S =Inch per Revolution (inch/rev.) HARDNESS ~ HRc21

STRENGTH ~ 800 N/mm 2 410 N/mm 2

DIAMETER N S N S N S N S N S N S

2.5 2800 .0010 7950 .0015 10700 .0015 7950 .0015 4225 .0010 1750 .0008

3.0 2500 .0020 6200 .0025 8450 .0025 6200 .0025 3350 .0020 1375 .0010

5.0 1600 .0025 3950 .0030 5350 .0030 3950 .0030 2125 .0025 875 .0015

HSSCo5, STRAIGHT SHANK PARABOLIC FLUTE 8.0 975 .0051 2490 .0071 3240 .0071 2490 .0071 1310 .0051 535 .0030

TAPER LENGTH 11.0 700 .0059 1740 .0079 2365 .0079 1740 .0079 935 .0059 535 .0030

19.0

410 .0091 1020 .0118 1370 .0118 1020 .0118 550 .0091 225 .0051

31.0 244 .0110 610 .0150 820 .0150 610 .0150 325 .0110 134 .0071

N = R.P.M

DL517 SERIES S =Inch per Revolution (inch/rev.)

P K

WORK

MATERIAL CARBON STEELS TOOL STEELS SOFT GREY HARD GREY

ALLOY STEELS HARDENED STEELS CAST IRON CAST IRON

HARDNESS HRc15 ~ 30 HRc20 ~ 40

STRENGTH 700 ~ 1000 N/mm 2 800 ~ 1200 N/mm 2

DIAMETER N S N S N S N S

~ 5/64 3990 .0023 2770 .0023 6920 .0027 4400 .0027

3/32 ~ 7/64 2440 .0031 1910 .0031 4640 .0043 2850 .0043

1/8 ~ 5/32 1990 .0035 1470 .0035 3500 .0055 2200 .0055

11/64 ~ 15/64 1590 .0039 1140 .0039 2810 .0055 1750 .0055

1/4 ~ 9/32 1140 .0055 810 .0055 1990 .0078 1260 .0078

19/64 ~ 5/16 980 .0059 690 .0059 1710 .0086 1100 .0086

21/64 ~ 23/64 900 .0066 650 .0066 1590 .0094 980 .0094

3/8 ~ 25/64 770 .0071 540 .0071 1420 .0110 850 .0110

13/32 ~ 7/16 730 .0078 510 .0078 1300 .0110 780 .0110

29/64 ~ 15/32 650 .0078 470 .0078 1180 .0110 730 .0110

31/64 ~ 1/2 590 .0078 410 .0078 1060 .0110 680 .0110

N = R.P.M

S =Inch per Revolution (inch/rev.)

234 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 235