Page 232 - YG 2019

P. 232

STRAIGHT STRAIGHT

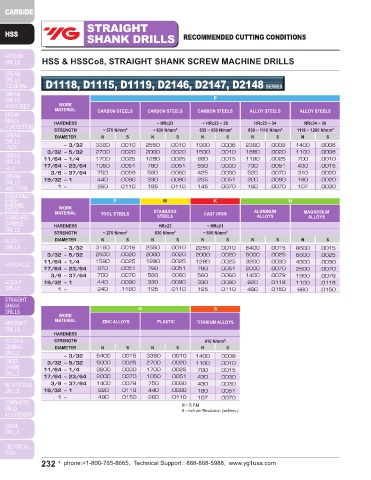

SHANK DRILLS RECOMMENDED CUTTING CONDITIONS SHANK DRILLS RECOMMENDED CUTTING CONDITIONS

HSSCo5, STRAIGHT SHANK PARABOLIC FLUTE SCREW MACHINE,

HSS & HSSCo8, STRAIGHT SHANK SCREW MACHINE DRILLS TiN COATED

D1118, D1115, D1119, D2146, D2147, D2148 SERIES DN514, DN516, DN515 SERIES

P P K

WORK WORK

TOOL STEELS

MATERIAL CARBON STEELS CARBON STEELS CARBON STEELS ALLOY STEELS ALLOY STEELS MATERIAL CARBON STEELS HARDENED STEELS SOFT GREY HARD GREY

ALLOY STEELS

CAST IRON

CAST IRON

HARDNESS ~ HRc23 ~ HRc23 ~ 28 HRc23 ~ 34 HRc34 ~ 38 HARDNESS HRc15 ~ 30 HRc20 ~ 40

STRENGTH ~ 570 N/mm 2 ~ 830 N/mm 2 830 ~ 950 N/mm 2 830 ~ 1110 N/mm 2 1110 ~ 1260 N/mm 2 STRENGTH 700 ~ 1000 N/mm 2 800 ~ 1200 N/mm 2

DIAMETER N S N S N S N S N S DIAMETER N S N S N S N S

~ 3/32 3380 .0010 2550 .0010 1900 .0006 2380 .0008 1400 .0006 ~ 5/64 2630 .0012 2100 .0010 4200 .0023 1680 .0500

3/32 ~ 5/32 2700 .0020 2000 .0020 1500 .0010 1880 .0020 1100 .0008 3/32 ~ 7/64 2100 .0015 1680 .0012 3300 .0031 1310 .0023

11/64 ~ 1/4 1700 .0025 1280 .0025 960 .0015 1190 .0025 700 .0010 1/8 ~ 5/32 1680 .0020 1310 .0015 2630 .0039 1050 .0031

17/64 ~ 23/64 1050 .0051 780 .0051 590 .0030 730 .0051 430 .0015 11/64 ~ 3/16 1310 .0023 1050 .0019 2100 .0051 840 .0039

3/8 ~ 37/64 750 .0059 560 .0060 425 .0030 520 .0070 310 .0020 13/64 ~ 15/64 1050 .0023 840 .0019 1680 .0051 660 .0039

19/32 ~ 1 440 .0090 330 .0090 255 .0051 300 .0090 180 .0020 1/4 ~ 9/32 840 .0031 660 .0023 1310 .0063 530 .0051

1 ~ 260 .0110 195 .0110 145 .0070 180 .0070 107 .0030 19/64 ~ 11/32 660 .0039 530 .0031 1050 .0078 420 .0067

23/64 ~ 7/16 530 .0051 420 .0039 840 .0098 330 .0082

P M K N 29/64 ~ 9/16 420 .0051 330 .0039 660 .0098 260 .0082

WORK 37/64 ~ 45/64 330 .0059 260 .0051 530 .0118 210 .0098

MATERIAL TOOL STEELS STAINLESS CAST IRON ALUMINUM MAGNESIUM 23/32 ~ 7/8 260 .0078 210 .0059 420 .0157 170 .0118

ALLOYS

STEELS

ALLOYS

57/64 ~ 1-1/8 210 .0098 170 .0078 330 .0196 130 .0196

HARDNESS HRc23 ~ HRc21 1-9/64 ~ 170 .0098 130 .0078 260 .0196 110 .0196

STRENGTH ~ 270 N/mm 2 830 N/mm 2 ~ 800 N/mm 2 N = R.P.M

DIAMETER N S N S N S N S N S S =Inch per Revolution (inch/rev.)

~ 3/32 3180 .0016 2550 .0010 2250 .0010 6400 .0015 8600 .0015

3/32 ~ 5/32 2500 .0020 2000 .0020 2000 .0020 5000 .0025 6800 .0025

11/64 ~ 1/4 1590 .0025 1280 .0025 1280 .0025 3200 .0030 4300 .0030

17/64 ~ 23/64 970 .0051 780 .0051 780 .0051 2000 .0070 2600 .0070

3/8 ~ 37/64 700 .0070 560 .0060 560 .0060 1400 .0078 1900 .0078

19/32 ~ 1 440 .0090 330 .0090 330 .0090 820 .0118 1100 .0118

1 ~ 240 .1180 195 .0110 195 .0110 490 .0150 660 .0150

N S

WORK

MATERIAL ZINC ALLOYS PLASTIC TITANIUM ALLOYS

HARDNESS

STRENGTH 410 N/mm 2

DIAMETER N S N S N S

~ 3/32 6400 .0015 3380 .0010 1400 .0008

3/32 ~ 5/32 5000 .0025 2700 .0020 1100 .0010

11/64 ~ 1/4 3200 .0030 1700 .0025 700 .0015

17/64 ~ 23/64 2000 .0070 1050 .0051 430 .0030

3/8 ~ 37/64 1400 .0078 750 .0060 430 .0030

19/32 ~ 1 820 .0118 440 .0090 180 .0051

1 ~ 490 .0150 260 .0110 107 .0070

N = R.P.M

S =Inch per Revolution (inch/rev.)

232 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 233