Page 758 - YG 2019

P. 758

4G MILL 4G MILL

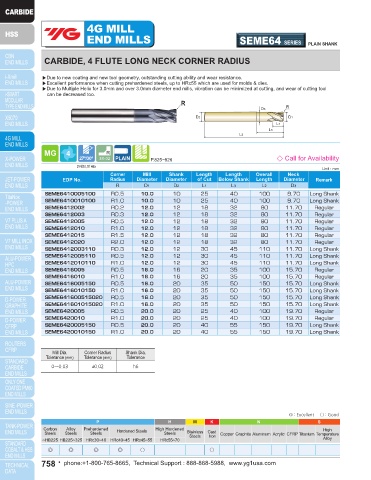

END MILLS SEME64 SERIES PLAIN SHANK END MILLS SEME35 SERIES PLAIN SHANK

CARBIDE, 4 FLUTE LONG NECK CORNER RADIUS CARBIDE, 2 FLUTE

▶Due to new coating and new tool geometry, outstanding cutting ability and wear resistance. ▶Due to new coating and new tool geometry, outstanding cutting ability and wear resitance.

▶Excellent performance when cutting prehardened steels, up to HRc55 which are used for molds & dies. ▶Excellent performance when cutting prehardened steels, up to HRc55 which are used for molds & dies.

▶Due to Multiple Helix for 3.0mm and over 3.0mm diameter end mills, vibration can be minimized at cutting, and wear of cutting tool ▶Due to sharp edge geometry at end tooth, cutting ability at working is increased.

can be decreased too.

R

↙ R

D3

D2 D1 D2 D1

L1

L1

L2

L3

L2

27º/30º 0.02 P.825~826 ◇ Call for Availability P.827 ◇ Call for Availability

D1<Ø3.0, 30˚ Helix

Unit : mm Unit : mm

Corner Mill Shank Length Length Overall Neck Mill Shank Length Overall

EDP No. Radius Diameter Diameter of Cut Below Shank Length Diameter Remark EDP No. Diameter Diameter of Cut Length

R D1 D2 L1 L3 L2 D3 D1 D2 L1 L2

SEME6410005100 R0.5 10.0 10 25 40 100 9.70 Long Shank SEME35001 0.1 4 0.2 40

SEME6410010100 R1.0 10.0 10 25 40 100 9.70 Long Shank SEME350015 0.15 4 0.3 40

SEME6412002 R0.2 12.0 12 18 32 80 11.70 Regular SEME35002 0.2 4 0.4 40

SEME6412003 R0.3 12.0 12 18 32 80 11.70 Regular SEME350025 0.25 4 0.5 40

SEME6412005 R0.5 12.0 12 18 32 80 11.70 Regular SEME35003 0.3 4 0.6 40

SEME6412010 R1.0 12.0 12 18 32 80 11.70 Regular SEME350035 0.35 4 0.7 40

SEME6412015 R1.5 12.0 12 18 32 80 11.70 Regular SEME35004 0.4 4 0.8 40

SEME6412020 R2.0 12.0 12 18 32 80 11.70 Regular SEME350045 0.45 4 0.9 40

SEME6412003110 R0.3 12.0 12 30 45 110 11.70 Long Shank SEME35005 0.5 4 1.0 40

SEME6412005110 R0.5 12.0 12 30 45 110 11.70 Long Shank SEME350055 0.55 4 1.1 40

SEME6412010110 R1.0 12.0 12 30 45 110 11.70 Long Shank SEME35006 0.6 4 1.2 40

SEME6416005 R0.5 16.0 16 20 35 100 15.70 Regular SEME350065 0.65 4 1.3 40

SEME6416010 R1.0 16.0 16 20 35 100 15.70 Regular SEME35007 0.7 4 1.4 40

SEME6416005150 R0.5 16.0 20 35 50 150 15.70 Long Shank SEME350075 0.75 4 1.5 40

SEME6416010150 R1.0 16.0 20 35 50 150 15.70 Long Shank SEME35008 0.8 4 1.6 40

SEME641600515020 R0.5 16.0 20 35 50 150 15.70 Long Shank SEME350085 0.85 4 1.7 40

SEME641601015020 R1.0 16.0 20 35 50 150 15.70 Long Shank SEME35009 0.9 4 1.8 40

SEME6420005 R0.5 20.0 20 25 40 100 19.70 Regular SEME350095 0.95 4 2 40

SEME6420010 R1.0 20.0 20 25 40 100 19.70 Regular SEME35010 1.0 6 2.5 50

SEME6420005150 R0.5 20.0 20 40 55 150 19.70 Long Shank SEME35012 1.2 6 3 50

SEME6420010150 R1.0 20.0 20 40 55 150 19.70 Long Shank ▶ NEXT PAGE

Mill Dia. Corner Radius Shank Dia.

Tolerance (mm) Tolerance (mm) Tolerance

0~-0.03 ±0.02 h6

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

Iron

Steels

~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

◎ ◎ ◎ ◎ ○ ○ ◎ ◎ ◎ ◎ ○ ○ ○

758 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 759