Page 763 - YG 2019

P. 763

4G MILL 4G MILL

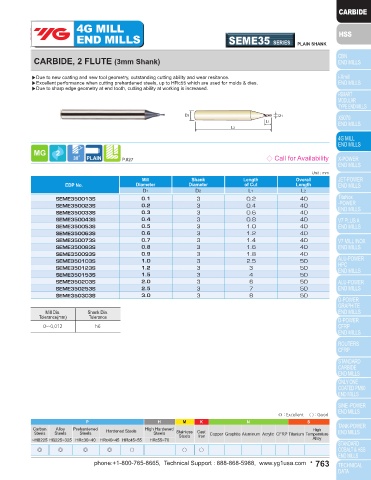

END MILLS SEME35 SERIES PLAIN SHANK END MILLS SEME35 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE (0.1mm a Unit / 4mm Shank) CARBIDE, 2 FLUTE (3mm Shank)

▶Due to new coating and new tool geometry, outstanding cutting ability and wear resitance. ▶Due to new coating and new tool geometry, outstanding cutting ability and wear resitance.

▶Excellent performance when cutting prehardened steels, up to HRc55 which are used for molds & dies. ▶Excellent performance when cutting prehardened steels, up to HRc55 which are used for molds & dies.

▶Due to sharp edge geometry at end tooth, cutting ability at working is increased. ▶Due to sharp edge geometry at end tooth, cutting ability at working is increased.

D2 D1

D2 D1

L1

L1

L2 L2

P.827 ◇ Call for Availability P.827 ◇ Call for Availability

Unit : mm Unit : mm

Mill Shank Length Overall Mill Shank Length Overall

EDP No. Diameter Diameter of Cut Length EDP No. Diameter Diameter of Cut Length

D1 D2 L1 L2 D1 D2 L1 L2

SEME350104S 1.0 1.0 2.5 50 SEME350013S 0.1 3 0.2 40

SEME350114S 1.1 1.1 3 50 SEME350023S 0.2 3 0.4 40

SEME350124S 1.2 1.2 3 50 SEME350033S 0.3 3 0.6 40

SEME350134S 1.3 1.3 3 50 SEME350043S 0.4 3 0.8 40

SEME350144S 1.4 1.4 4 50 SEME350053S 0.5 3 1.0 40

SEME350154S 1.5 1.5 4 50 SEME350063S 0.6 3 1.2 40

SEME350164S 1.6 1.6 4 50 SEME350073S 0.7 3 1.4 40

SEME350174S 1.7 1.7 4 50 SEME350083S 0.8 3 1.6 40

SEME350184S 1.8 1.8 5 50 SEME350093S 0.9 3 1.8 40

SEME350194S 1.9 1.9 5 50 SEME350103S 1.0 3 2.5 50

SEME350204S 2.0 2.0 6 50 SEME350123S 1.2 3 3 50

SEME350214S 2.1 2.1 6 50 SEME350153S 1.5 3 4 50

SEME350224S 2.2 2.2 6 50 SEME350203S 2.0 3 6 50

SEME350234S 2.3 2.3 6 50 SEME350253S 2.5 3 7 50

SEME350244S 2.4 2.4 6 50 SEME350303S 3.0 3 8 50

SEME350254S 2.5 2.5 8 50

SEME350264S 2.6 2.6 8 50 Mill Dia. Shank Dia.

SEME350274S 2.7 2.7 8 50 Tolerance(mm) Tolerance

SEME350284S 2.8 2.8 8 50 0~-0.012 h6

SEME350294S 2.9 2.9 8 50

SEME350304S 3.0 3.0 8 50

SEME350354S 3.5 3.5 10 50

SEME350404S 4.0 4.0 10 50

SEME350404S080 4.0 4.0 10 80

▶ NEXT PAGE

Mill Dia. Shank Dia.

Tolerance(mm) Tolerance

0~-0.012 h6

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Steels

Iron

~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

◎ ◎ ◎ ◎ ○ ○ ○ ◎ ◎ ◎ ◎ ○ ○ ○

762 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 763