Page 780 - YG 2019

P. 780

4G MILL 4G MILL

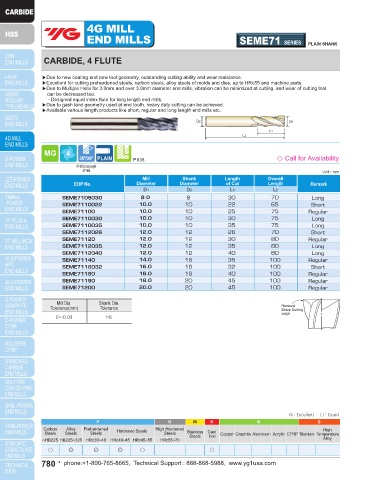

END MILLS SEME71 SERIES PLAIN SHANK END MILLS SEME72 SERIES PLAIN SHANK

CARBIDE, 4 FLUTE CARBIDE, 4 FLUTE LONG LENGTH

▶Due to new coating and new tool geometry, outstanding cutting ability and wear resistance. ▶ Due to new coating and new tool geometry, outstanding cutting ability and wear resistance.

▶Excellent for cutting prehardened steels, carbon steels, alloy steels of molds and dies, up to HRc55 and machine parts. ▶ Excellent performance when cutting prehardened steels, up to HRc55 which are used for molds & dies.

▶Due to Multiple Helix for 3.0mm and over 3.0mm diameter end mills, vibration can be minimized at cutting, and wear of cutting tool ▶ Available various length of cut and overall length products.

can be decreased too.

- Designed equal index flute for long length end mills.

▶Due to gash land geometry used at end tooth, heavy duty cutting can be achieved.

▶Available various length products like short, regular and long length end mills etc.

D2 D1

D2 D1 L1

L1 L2

L2

35º/38º P.836 ◇ Call for Availability P.837~838 ◇ Call for Availability

D1<Ø3.0, Long Length

38˚ Helix Unit : mm Unit : mm

Mill Shank Length Overall Mill Shank Length Overall

EDP No. Diameter Diameter of Cut Length Remark EDP No. Diameter Diameter of Cut Length

D1 D2 L1 L2 D1 D2 L1 L2

SEME7108030 8.0 8 30 70 Long SEME7201003 1.0 6 3 60

SEME7110022 10.0 10 22 65 Short SEME7201004 1.0 6 4 60

SEME71100 10.0 10 25 75 Regular SEME7201005 1.0 6 5 60

SEME7110030 10.0 10 30 75 Long SEME7201006 1.0 6 6 60

SEME7110035 10.0 10 35 75 Long SEME7201007 1.0 6 7 60

SEME7112026 12.0 12 26 70 Short SEME7201008 1.0 6 8 60

SEME71120 12.0 12 30 80 Regular SEME7201010 1.0 6 10 60

SEME7112035 12.0 12 35 80 Long SEME7201012 1.0 6 12 60

SEME7112040 12.0 12 40 80 Long SEME7201204 1.2 6 4 60

SEME71140 14.0 16 35 100 Regular SEME7201206 1.2 6 6 60

SEME7116032 16.0 16 32 100 Short SEME7201208 1.2 6 8 60

SEME71160 16.0 16 40 100 Regular SEME7201210 1.2 6 10 60

SEME71180 18.0 20 45 100 Regular SEME7201212 1.2 6 12 60

SEME71200 20.0 20 45 100 Regular SEME7201506 1.5 6 6 60

SEME7201508 1.5 6 8 60

Mill Dia. Shank Dia. SEME7201510 1.5 6 10 60

Tolerance(mm) Tolerance SEME7201512 1.5 6 12 60

SEME7201514 1.5 6 14 60

0~-0.03 h6

SEME7201516 1.5 6 16 60

SEME7202008 2.0 6 8 60

SEME7202010 2.0 6 10 60

SEME7202012 2.0 6 12 60

SEME7202014 2.0 6 14 60

SEME7202016 2.0 6 16 60

SEME7202510 2.5 6 10 60

SEME7202512 2.5 6 12 60

SEME7202516 2.5 6 16 60

SEME7202520 2.5 6 20 60

▶ NEXT PAGE

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

Steels

Iron

~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ◎ ◎ ◎ ◎ ○ ○

780 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 781