Page 809 - YG 2019

P. 809

4G MILL 4G MILL

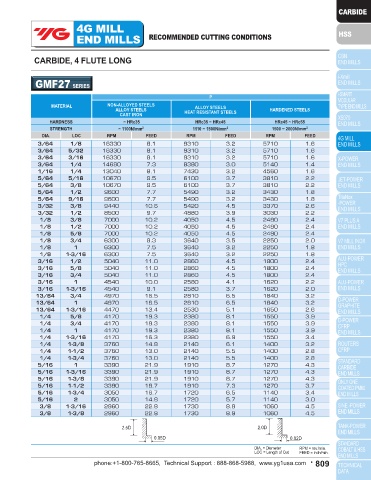

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

CARBIDE, 4 FLUTE CARBIDE, 4 FLUTE LONG

GMF25, GMF26 SERIES GMF27 SERIES

P M P

NON-ALLOYED STEELS MATERIAL NON-ALLOYED STEELS

MATERIAL ALLOY STEELS ALLOY STEELS HARDENED STEELS STAINLESS STEELS ALLOY STEELS ALLOY STEELS HARDENED STEELS

CAST IRON HEAT RESISTANT STEELS CAST IRON HEAT RESISTANT STEELS

HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55 HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55

STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED DIA. LOC RPM FEED RPM FEED RPM FEED

3/64 22680 11.8 13610 7.1 9070 2.1 11340 5.9 3/64 1/8 16330 8.1 9310 3.2 5710 1.6

1/16 17720 11.3 10630 6.9 7090 2.1 8860 5.9 3/64 5/32 16330 8.1 9310 3.2 5710 1.6

5/64 14560 12.1 9520 7.4 6350 2.2 7940 6.1 3/64 3/16 16330 8.1 9310 3.2 5710 1.6

3/32 13440 13.6 8610 8.5 5510 2.6 7170 7.2 3/64 1/4 14690 7.3 8380 3.0 5140 1.4

1/8 10540 13.0 6570 8.2 3970 2.4 5460 6.9 1/16 1/4 13040 8.1 7430 3.2 4560 1.6

9/64 10090 18.8 6230 11.7 3860 2.6 5200 9.5 5/64 5/16 10670 9.5 6100 3.7 3810 2.2

3/16 8180 24.0 4960 14.5 3110 2.6 4160 11.9 5/64 3/8 10670 9.5 6100 3.7 3810 2.2

13/64 7640 25.1 4580 15.2 2810 3.0 3830 12.6 5/64 1/2 9600 7.7 5490 3.2 3430 1.8

7/32 7330 27.1 4410 16.5 2670 3.3 3710 13.4 5/64 9/16 9600 7.7 5490 3.2 3430 1.8

1/4 6570 27.1 3970 16.7 2360 3.3 3350 13.4 3/32 3/8 9440 10.6 5420 4.5 3370 2.6

17/64 6290 27.5 3800 16.5 2310 3.6 3200 13.8 3/32 1/2 8500 9.7 4880 3.9 3030 2.2

9/32 5980 27.7 3610 15.9 2250 3.9 3030 13.9 1/8 3/8 7000 10.2 4050 4.5 2490 2.4

19/64 5650 28.7 3390 16.1 2190 4.3 2840 14.3 1/8 1/2 7000 10.2 4050 4.5 2490 2.4

5/16 5290 29.6 3170 15.9 2120 4.6 2650 14.7 1/8 5/8 7000 10.2 4050 4.5 2490 2.4

11/32 4830 27.5 2910 14.5 1950 4.1 2420 13.6 1/8 3/4 6300 8.3 3640 3.5 2250 2.0

23/64 4590 26.9 2790 13.9 1870 4.1 2330 13.2 1/8 1 6300 7.5 3640 3.2 2250 1.8

3/8 4280 26.5 2620 13.0 1780 3.9 2200 13.0 1/8 1-3/16 6300 7.5 3640 3.2 2250 1.8

7/16 3710 23.2 2280 11.2 1560 3.5 1880 11.0 3/16 1/2 5040 11.0 2860 4.5 1800 2.4

1/2 3240 20.7 1980 9.9 1370 3.2 1610 9.5 3/16 5/8 5040 11.0 2860 4.5 1800 2.4

9/16 3030 18.8 1860 9.1 1260 2.9 1510 8.9 3/16 3/4 5040 11.0 2860 4.5 1800 2.4

5/8 2770 17.6 1710 8.5 1140 2.5 1390 8.3 3/16 1 4540 10.0 2580 4.1 1620 2.2

3/4 2200 13.9 1400 7.0 890 1.6 1100 6.4 3/16 1-3/16 4540 9.1 2580 3.7 1620 2.0

13/64 3/4 4970 16.5 2810 6.5 1840 3.2

13/64 1 4970 16.5 2810 6.5 1840 3.2

1.0D 13/64 1-3/16 4470 13.4 2530 5.1 1650 2.6

1/4 5/8 4170 19.3 2380 8.1 1550 3.9

0.05D 1/4 3/4 4170 19.3 2380 8.1 1550 3.9

1/4 1 4170 19.3 2380 8.1 1550 3.9

RPM = rev./min.

FEED = inch/min. 1/4 1-3/16 4170 16.3 2380 6.9 1550 3.4

1/4 1-3/8 3760 14.8 2140 6.1 1400 3.2

1/4 1-1/2 3760 13.0 2140 5.5 1400 2.8

1/4 1-3/4 3760 13.0 2140 5.5 1400 2.8

5/16 1 3390 21.9 1910 8.7 1270 4.3

5/16 1-3/16 3390 21.9 1910 8.7 1270 4.3

5/16 1-3/8 3390 21.9 1910 8.7 1270 4.3

5/16 1-1/2 3390 18.7 1910 7.3 1270 3.7

5/16 1-3/4 3050 16.7 1720 6.5 1140 3.4

5/16 2 3050 14.8 1720 5.7 1140 3.0

3/8 1-3/16 2960 22.8 1730 8.9 1060 4.5

3/8 1-3/8 2960 22.8 1730 8.9 1060 4.5

2.5D 2.0D

0.05D 0.02D

DIA. = Diameter RPM = rev./min.

LOC = Length of Cut FEED = inch/min.

808 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 809