Page 812 - YG 2019

P. 812

4G MILL 4G MILL

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

CARBIDE, 4&5 FLUTE MULTIPLE HELIX CORNER RADIUS

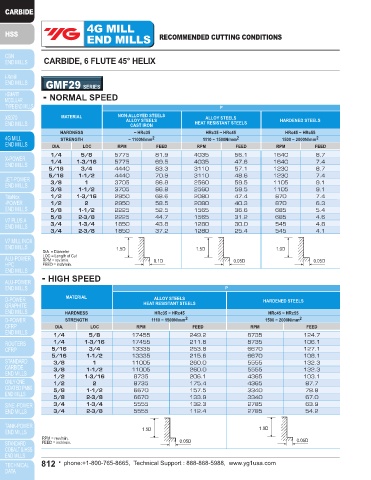

CARBIDE, 6 FLUTE 45° HELIX - SLOTTING

GMF29 SERIES G907, G928, G908, G929, G909, G930 SERIES

- NORMAL SPEED P

MATERIAL ALLOY STEELS, CARBON STEELS ALLOY STEELS, CARBON STEELS

P TOOL STEELS TOOL STEELS, CAST IRON

MATERIAL NON-ALLOYED STEELS ALLOY STEELS CAST IRON PREHARDENED STEELS

ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS HARDNESS ~ HRc25 HRc25 ~ HRc40

CAST IRON DIAMETER

HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55 INCH METRIC RPM FEED RPM FEED

STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 1/4 6.0 12000 61.0 10600 43.3

DIA. LOC RPM FEED RPM FEED RPM FEED 5/16 8.0 9000 65.0 8100 46.5

1/4 5/8 5775 81.9 4035 56.1 1640 8.7 3/8 10.0 7200 65.0 6400 46.5

1/4 1-3/16 5775 69.5 4035 47.6 1640 7.4 1/2 12.0 6000 60.6 5400 44.9

5/16 3/4 4440 83.3 3110 57.1 1230 8.7 5/8 16.0 4500 59.1 4100 41.3

5/16 1-1/2 4440 70.9 3110 48.6 1230 7.4 3/4 20.0 3600 52.4 3200 35.4

3/8 1 3705 86.8 2560 59.5 1105 9.1 1 - 2900 46.4 2600 32.5

3/8 1-1/2 3705 86.8 2560 59.5 1105 9.1

1/2 1-3/16 2950 68.6 2080 47.4 870 7.4 D D

1/2 2 2950 58.5 2080 40.3 870 6.3

5/8 1-1/2 2225 52.5 1565 36.6 685 5.4 1.0D 0.8D

5/8 2-3/8 2225 44.7 1565 31.2 685 4.6

3/4 1-3/4 1850 43.8 1280 30.0 545 4.8 RPM = rev./min.

3/4 2-3/8 1850 37.2 1280 25.4 545 4.1 FEED = inch/min.

1.5D 1.5D 1.0D

DIA. = Diameter

LOC = Length of Cut CARBIDE, 4&5 FLUTE MULTIPLE HELIX CORNER RADIUS

RPM = rev./min. 0.1D 0.05D 0.05D

FEED = inch/min. - SIDE CUTTING

- HIGH SPEED

P G907, G928, G908, G929, G909, G930 SERIES

MATERIAL ALLOY STEELS P

HEAT RESISTANT STEELS HARDENED STEELS

MATERIAL ALLOY STEELS, CARBON STEELS ALLOY STEELS, CARBON STEELS

HARDNESS HRc35 ~ HRc45 HRc45 ~ HRc55 TOOL STEELS TOOL STEELS, CAST IRON

PREHARDENED STEELS

CAST IRON

STRENGTH 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIA. LOC RPM FEED RPM FEED HARDNESS ~ HRc25 HRc25 ~ HRc40

DIAMETER

1/4 5/8 17455 249.2 8735 124.7 INCH METRIC RPM FEED RPM FEED

1/4 1-3/16 17455 211.8 8735 106.1 1/4 6.0 15800 101.2 14300 72.8

5/16 3/4 13335 253.8 6670 127.1 5/16 8.0 11900 106.3 10700 76.8

5/16 1-1/2 13335 215.6 6670 108.1 3/8 10.0 9500 106.3 8500 76.8

3/8 1 11005 260.0 5555 132.3 1/2 12.0 8000 101.2 7100 72.8

3/8 1-1/2 11005 260.0 5555 132.3 5/8 16.0 6000 96.5 5400 69.9

1/2 1-3/16 8735 206.1 4365 103.1 3/4 20.0 4800 84.3 4300 59.1

1/2 2 8735 175.4 4365 87.7 1 - 3800 75.3 3400 49.3

5/8 1-1/2 6670 157.5 3340 78.8

5/8 2-3/8 6670 133.9 3340 67.0

3/4 1-3/4 5555 132.3 2785 63.9 1.0D 1.0D

3/4 2-3/8 5555 112.4 2785 54.2

0.5D 0.35D

1.5D 1.0D RPM = rev./min.

FEED = inch/min.

RPM = rev./min. 0.05D

FEED = inch/min. 0.05D

812 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 813