Page 807 - YG 2019

P. 807

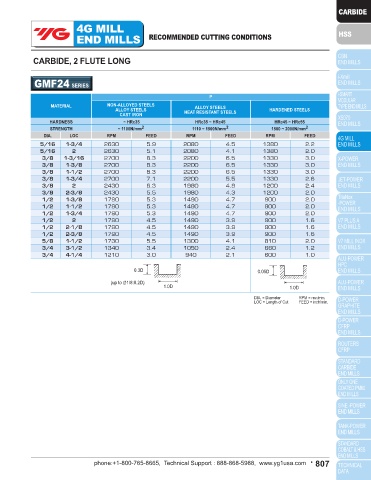

4G MILL 4G MILL

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

CARBIDE, 2 FLUTE LONG CARBIDE, 2 FLUTE LONG

GMF24 SERIES GMF24 SERIES

P P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS

CAST IRON CAST IRON

HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55 HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55

STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIA. LOC RPM FEED RPM FEED RPM FEED DIA. LOC RPM FEED RPM FEED RPM FEED

3/64 1/8 13710 3.0 10970 2.6 6860 1.2 5/16 1-3/4 2630 5.9 2080 4.5 1380 2.2

3/64 5/32 13710 3.0 10970 2.6 6860 1.2 5/16 2 2630 5.1 2080 4.1 1380 2.0

3/64 1/4 12340 2.8 9870 2.4 6170 1.0 3/8 1-3/16 2700 8.3 2200 6.5 1330 3.0

3/64 5/16 12340 2.4 9870 2.2 6170 1.0 3/8 1-3/8 2700 8.3 2200 6.5 1330 3.0

3/64 3/8 12340 2.2 9870 2.0 6170 0.8 3/8 1-1/2 2700 8.3 2200 6.5 1330 3.0

1/16 1/4 10000 2.8 8000 2.4 5000 1.0 3/8 1-3/4 2700 7.1 2200 5.5 1330 2.6

1/16 5/16 10000 2.8 8000 2.4 5000 1.0 3/8 2 2430 6.3 1980 4.9 1200 2.4

1/16 3/8 9000 2.4 7200 2.0 4500 0.8 3/8 2-3/8 2430 5.5 1980 4.3 1200 2.0

1/16 1/2 9000 2.0 7200 1.8 4500 0.8 1/2 1-3/8 1790 5.3 1490 4.7 900 2.0

1/16 5/8 9000 2.0 7200 1.8 4500 0.8 1/2 1-1/2 1790 5.3 1490 4.7 900 2.0

5/64 5/16 9210 3.4 7370 2.8 4610 1.4 1/2 1-3/4 1790 5.3 1490 4.7 900 2.0

5/64 3/8 9210 3.4 7370 2.8 4610 1.4 1/2 2 1790 4.5 1490 3.9 900 1.6

5/64 1/2 8290 2.8 6640 2.4 4150 1.2 1/2 2-1/8 1790 4.5 1490 3.9 900 1.6

5/64 5/8 8290 2.4 6640 2.0 4150 1.0 1/2 2-3/8 1790 4.5 1490 3.9 900 1.6

3/32 5/8 7640 3.4 6150 2.8 3820 1.4 5/8 1-1/2 1730 5.5 1300 4.1 810 2.0

1/8 3/8 5670 3.5 4600 3.0 2830 1.4 3/4 3-1/2 1340 3.4 1050 2.4 660 1.2

1/8 1/2 5670 3.5 4600 3.0 2830 1.4 3/4 4-1/4 1210 3.0 940 2.1 600 1.0

1/8 5/8 5670 3.5 4600 3.0 2830 1.4

1/8 3/4 5100 2.8 4140 2.4 2550 1.2 0.3D 0.05D

1/8 1 5100 2.6 4140 2.2 2550 1.0

3/16 1/2 3630 3.4 2890 2.8 1820 1.4 (up to Ø1/8:0.2D)

3/16 5/8 3630 3.4 2890 2.8 1820 1.4 1.0D 1.0D

3/16 3/4 3630 3.4 2890 2.8 1820 1.4 DIA. = Diameter RPM = rev./min.

3/16 1 3270 3.0 2600 2.6 1640 1.2 LOC = Length of Cut FEED = inch/min.

3/16 1-3/16 3270 2.8 2600 2.2 1640 1.2

13/64 3/4 4130 5.5 3270 4.5 2140 2.0

13/64 1 4130 5.5 3270 4.5 2140 2.0

13/64 1-3/16 3720 4.5 2940 3.7 1930 1.6

13/64 1-1/2 3720 4.5 2940 3.7 1930 1.6

1/4 5/8 3390 6.3 2720 5.3 1760 2.4

1/4 3/4 3390 6.3 2720 5.3 1760 2.4

1/4 1 3390 6.3 2720 5.3 1760 2.4

1/4 1-3/16 3390 5.3 2720 4.5 1760 2.2

1/4 1-3/8 3050 4.9 2450 3.9 1580 2.0

1/4 1-1/2 3050 4.3 2450 3.5 1580 1.6

1/4 1-3/4 3050 4.3 2450 3.5 1580 1.6

5/16 1 2930 7.7 2320 5.9 1530 2.8

5/16 1-3/16 2930 7.7 2320 5.9 1530 2.8

5/16 1-3/8 2930 7.7 2320 5.9 1530 2.8

5/16 1-1/2 2930 6.5 2320 5.1 1530 2.4

DIA. = Diameter 0.3D

LOC = Length of Cut 0.05D

RPM = rev./min.

FEED = inch/min. (up to Ø1/8:0.2D) 1.0D 1.0D

806 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 807