Page 869 - YG 2019

P. 869

X-POWER X-POWER

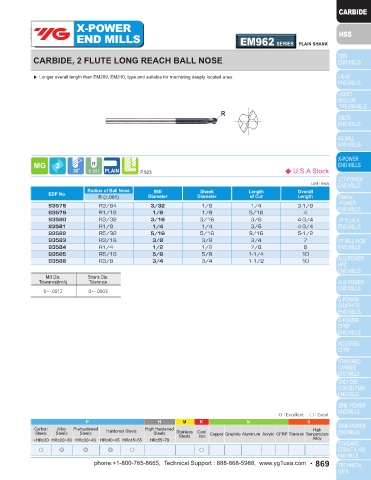

END MILLS EM961 SERIES PLAIN SHANK END MILLS EM962 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE MEDIUM LENGTH BALL NOSE CARBIDE, 2 FLUTE LONG REACH BALL NOSE

▶ Deep slotting milling is possible by reduced neck. ▶ Longer overall length than EM209, EM210, type and suitable for machining deeply located area.

▶ High efficiency milling is possible in deep slotting with projection of the end mill being long.

R

R D3

↙ R

D2 D1 ↙

L1

L3

L2

P.922 ◆ U.S.A Stock P.923 ◆ U.S.A Stock

Unit : Inch Unit : Inch

Radius of Mill Shank Length Length Overall Neck EDP No. Radius of Ball Nose Mill Shank Length Overall

EDP No. Ball Nose Diameter Diameter of Cut Below Shank Length Diameter R (±.001) Diameter Diameter of Cut Length

R (±.001) D1 D2 L1 L3 L2 D3 93578 R3/64 3/32 1/8 1/4 3-1/8

93517 R1/16 1/8 1/4 5/16 - 2-3/4 - 93579 R1/16 1/8 1/8 5/16 4

93518 R3/32 3/16 1/4 1/2 - 3-1/8 - 93580 R3/32 3/16 3/16 3/8 4-3/4

93519 R1/8 1/4 1/4 1/2 7/8 3-1/8 .242 93581 R1/8 1/4 1/4 3/8 4-3/4

93520 R5/32 5/16 5/16 9/16 1-1/16 3-1/2 .305 93582 R5/32 5/16 5/16 9/16 5-1/2

93521 R3/16 3/8 3/8 3/4 1-1/4 4 .367 93583 R3/16 3/8 3/8 3/4 7

93522 R1/4 1/2 1/2 7/8 1-3/8 4-1/4 .492 93584 R1/4 1/2 1/2 7/8 8

93523 R5/16 5/8 5/8 1-1/4 2 5-1/2 .617 93585 R5/16 5/8 5/8 1-1/4 10

93524 R3/8 3/4 3/4 1-1/2 2-1/4 6-1/4 .742 93586 R3/8 3/4 3/4 1-1/2 10

93525 R1/2 1 1 2-1/8 3 7 .992

Mill Dia. Shank Dia.

Mill Dia. Shank Dia. Tolerance(inch) Tolerance

Tolerance(inch) Tolerance

0~-.0012 0~-.0003

0~-.0012 0~-.0003

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Iron

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○

868 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 869