Page 873 - YG 2019

P. 873

X-POWER X-POWER

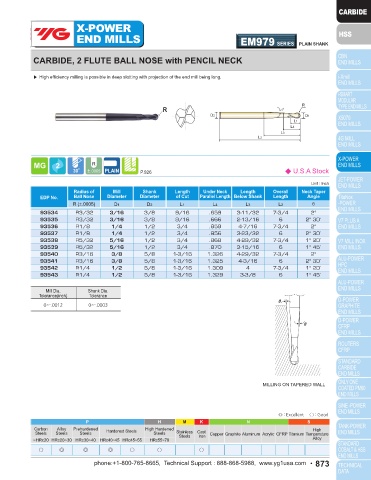

END MILLS EM963 SERIES PLAIN SHANK END MILLS EM979 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE BALL NOSE with TAPER NECK CARBIDE, 2 FLUTE BALL NOSE with PENCIL NECK

▶ High efficiency milling is possible in deep slotting with projection of the end mill being long. ▶ High efficiency milling is possible in deep slotting with projection of the end mill being long.

R D3 R R R

↙ D2 D1 ↙ D2 D1

L1 L1

L4 L4

L3 L3

L2 L2

P.925 U.S.A Stock P.926 ◆ U.S.A Stock

Unit : Inch Unit : Inch

Radius of Mill Shank Length Under Neck Length Overall Neck Neck Taper Radius of Mill Shank Length Under Neck Length Overall Neck Taper

EDP No. Ball Nose Diameter Diameter of Cut Parallel Length Below Shank Length Diameter Angle EDP No. Ball Nose Diameter Diameter of Cut Parallel Length Below Shank Length Angle

R (±.0005) D1 D2 L1 L4 L3 L2 D3 θ R (±.0005) D1 D2 L1 L4 L3 L2 θ

93526 R1/32 1/16 1/4 5/32 15/64 7/8 2-3/8 .096 1° 30´ 93534 R3/32 3/16 3/8 9/16 .659 3-11/32 7-3/4 2°

93527 R1/32 1/16 1/4 5/32 15/64 1-5/8 3-1/8 .208 3° 93535 R3/32 3/16 3/8 9/16 .666 2-13/16 6 2° 30´

93528 R1/16 1/8 1/4 1/4 21/64 2-1/16 3-5/8 .216 1° 30´ 93536 R1/8 1/4 1/2 3/4 .859 4-7/16 7-3/4 2°

93529 R3/32 3/16 3/8 3/8 29/64 2-3/8 4-3/8 .288 1° 30´ 93537 R1/8 1/4 1/2 3/4 .856 3-23/32 6 2° 30´

93530 R1/8 1/4 3/8 1/2 5/8 2-1/16 4-3/8 .325 1° 30´ 93538 R5/32 5/16 1/2 3/4 .868 4-29/32 7-3/4 1° 20´

93531 R5/32 5/16 1/2 9/16 11/16 2-1/16 4-3/4 .385 1° 30´ 93539 R5/32 5/16 1/2 3/4 .870 3-15/16 6 1° 45´

93532 R3/16 3/8 1/2 11/16 13/16 2-3/8 5-1/16 .458 1° 30´ 93540 R3/16 3/8 5/8 1-3/16 1.326 4-29/32 7-3/4 2°

93533 R1/4 1/2 3/4 7/8 1 3-1/4 6-3/8 .618 1° 30´ 93541 R3/16 3/8 5/8 1-3/16 1.325 4-3/16 6 2° 30´

93542 R1/4 1/2 5/8 1-3/16 1.309 4 7-3/4 1° 20´

Mill Dia. Shank Dia. 93543 R1/4 1/2 5/8 1-3/16 1.329 3-3/8 6 1° 45´

Tolerance(inch) Tolerance

0~-.0012 0~-.0003 Mill Dia. Shank Dia.

Tolerance(inch) Tolerance

0~-.0012 0~-.0003

MILLING ON TAPERED WALL

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Iron

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○ ○

872 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 873