Page 875 - YG 2019

P. 875

X-POWER X-POWER

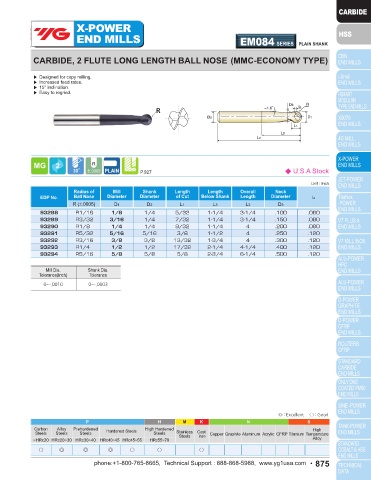

END MILLS END MILLS EM084 SERIES PLAIN SHANK

X-POWER BALL NOSE END MILLS - MMC CARBIDE, 2 FLUTE LONG LENGTH BALL NOSE (MMC-ECONOMY TYPE)

▶ Designed for copy milling.

▶ Increased feed rates.

Useful Field Area ▶ 15° inclination.

▶ Easy to regrind.

• Die & Mold making, Turbine manufacturing and Aircraft Industry, etc.

• Difficult 3-D Forms. R

• Profiling of up to HRc 65 high hardened steels and Alloy steels, Nickelbase alloys, Titanium alloys. ↙

Characteristics

• Ultra micro grain carbide which increase both toughness and hardness.

• YG-1’s unique X-POWER coating suitable for dry cutting and high speed cutting.

• Oustanding tool geometry and sphere shape ball enables more increased tool life and higher speed and feed operation.

Surpassing Milling Operation P.927 ◆ U.S.A Stock

Unit : Inch

Radius of Mill Shank Length Length Overall Neck

Ball Nose

Operating angle 14° ~ 16°, higher speed and EDP No. R (±.0005) Diameter Diameter of Cut Below Shank Length Diameter Iz

D1

L3

L2

D3

D2

L1

feed are possible by decreased cutting 93288 R1/16 1/8 1/4 5/32 1-1/4 3-1/4 .100 .060

resistance at the cutting edges contacting the 93289 R3/32 3/16 1/4 7/32 1-1/4 3-1/4 .150 .080

workpiece. 93290 R1/8 1/4 1/4 9/32 1-1/4 4 .200 .080

93291 R5/32 5/16 5/16 3/8 1-1/2 4 .250 .120

93292 R3/16 3/8 3/8 13/32 1-3/4 4 .300 .120

Excellent surface finish and faster milling 93293 R1/4 1/2 1/2 17/32 2-1/4 4-1/4 .400 .120

process. 93294 R5/16 5/8 5/8 5/8 2-3/4 6-1/4 .500 .120

Mill Dia. Shank Dia.

Enable to milling with higher speed and feed Tolerance(inch) Tolerance

when Back Milling. 0~-.0010 0~-.0003

Favorable Back Milling Unfavorable Drilling

Inclination (ap=0.5D)

When 15° inclination milling operation, more

productivity and higher speed and feed are

possible.

Decreased cutting force.

Excellent surface roughness and brightness.

◎ : Excellent ◯ : Good

P H M K N S

Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

Unfavorable Profiling Favorable Profiling

○ ◎ ◎ ◎ ○ ○ ○

874 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 875