Page 905 - YG 2019

P. 905

X-POWER X-POWER

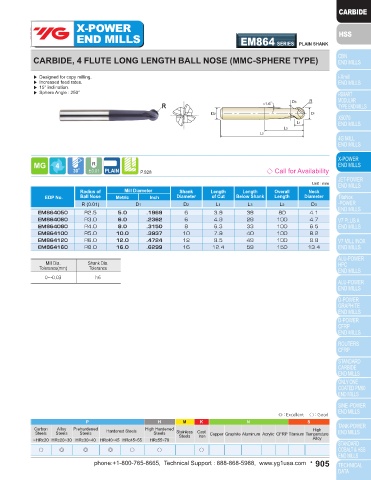

END MILLS EM863 SERIES PLAIN SHANK END MILLS EM864 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE LONG LENGTH BALL NOSE (MMC-SPHERE TYPE) CARBIDE, 4 FLUTE LONG LENGTH BALL NOSE (MMC-SPHERE TYPE)

▶ Designed for copy milling. ▶ Designed for copy milling.

▶ Increased feed rates. ▶ Increased feed rates.

▶ 15° inclination. ▶ 15° inclination.

▶ Sphere Angle : 250° ▶ Sphere Angle : 250°

R R

↙ ↙

P.927 ◇ Call for Availability P.928 ◇ Call for Availability

Unit : mm Unit : mm

Radius of Mill Diameter Shank Length Length Overall Neck Radius of Mill Diameter Shank Length Length Overall Neck

EDP No. Ball Nose Metric Inch Diameter of Cut Below Shank Length Diameter EDP No. Ball Nose Metric Inch Diameter of Cut Below Shank Length Diameter

R (±0.01) D1 D2 L1 L3 L2 D3 R (0.01) D1 D2 L1 L3 L2 D3

EM863030 R1.5 3.0 .1181 6 2.3 30 80 2.5 EM864050 R2.5 5.0 .1969 6 3.9 38 80 4.1

EM863040 R2.0 4.0 .1575 6 3.1 30 80 3.3 EM864060 R3.0 6.0 .2362 6 4.9 28 100 4.7

EM863050 R2.5 5.0 .1969 6 3.9 38 80 4.1 EM864080 R4.0 8.0 .3150 8 6.3 33 100 6.5

EM863060 R3.0 6.0 .2362 6 4.9 28 100 4.7 EM864100 R5.0 10.0 .3937 10 7.9 40 100 8.2

EM863080 R4.0 8.0 .3150 8 6.3 33 100 6.5 EM864120 R6.0 12.0 .4724 12 9.5 49 100 9.8

EM863100 R5.0 10.0 .3937 10 7.9 40 100 8.2 EM864160 R8.0 16.0 .6299 16 12.4 59 150 13.4

EM863120 R6.0 12.0 .4724 12 9.5 49 100 9.8

EM863160 R8.0 16.0 .6299 16 12.4 59 150 13.4 Mill Dia. Shank Dia.

Tolerance(mm) Tolerance

Mill Dia. Shank Dia. 0~-0.03 h6

Tolerance(mm) Tolerance

0~-0.03 h6

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○ ○

904 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 905