Page 909 - YG 2019

P. 909

X-POWER X-POWER

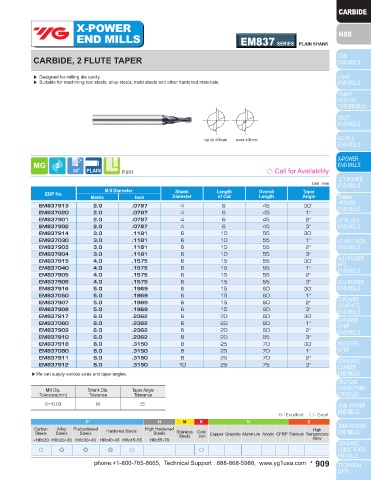

END MILLS EM833 SERIES PLAIN SHANK END MILLS EM837 SERIES PLAIN SHANK

CARBIDE, 3&4 FLUTE 20° HELIX LONG LENGTH CARBIDE, 2 FLUTE TAPER

FINE PITCH ROUGHING BALL NOSE

▶ Designed to machine tool steel, alloy steel, mold steel and other high hardened materials. ▶ Designed for milling die cavity.

▶ High velocity milling of hardened steels. ▶ Suitable for machining tool steels, alloy steels, mold steels and other hardened materials.

▶ For dry and wet milling.

▶ Fast chip ejection.

R

↙

up to ø3mm over ø3mm 8Flute Corner Radius 8Flute Corner Radius 6Flute Corner Radius 8Flute Square 6Flute Square

2Flute Square

P.930 ◇ Call for Availability P.931 ◇ Call for Availability

Unit : mm Unit : mm

Radius of Mill Diameter Shank EDP No. Mill Diameter Shank Length Overall Taper

EDP No. Ball Nose Metric Inch Diameter Length Overall No. of Metric Inch Diameter of Cut Length Angle

of Cut

Length

Flute

R (±0.02) h10 h6 EM837913 2.0 .0787 4 6 45 30´

EM833060 R3.0 6.0 .2362 6 16 57 3 EM837020 2.0 .0787 4 6 45 1°

EM833080 R4.0 8.0 .3150 8 16 63 3 EM837901 2.0 .0787 4 6 45 2°

EM833100 R5.0 10.0 .3937 10 22 72 4 EM837902 2.0 .0787 4 6 45 3°

EM833120 R6.0 12.0 .4724 12 26 83 4 EM837914 3.0 .1181 6 10 55 30´

EM833140 R7.0 14.0 .5512 14 26 83 4 EM837030 3.0 .1181 6 10 55 1°

EM833160 R8.0 16.0 .6299 16 32 92 4 EM837903 3.0 .1181 6 10 55 2°

EM833180 R9.0 18.0 .7087 18 32 92 4 EM837904 3.0 .1181 6 10 55 3°

EM833200 R10.0 20.0 .7874 20 38 104 4 EM837915 4.0 .1575 6 15 55 30´

EM837040 4.0 .1575 6 15 55 1°

Tolerances according to DIN 7160 & 7161 EM837905 4.0 .1575 6 15 55 2°

EM837906 4.0 .1575 6 15 55 3°

Tolerance range in µm

Nominal-Diameter in mm EM837916 5.0 .1969 6 15 60 30´

from 1 to 3 over 3 to 6 over 6 to 10 over 10 to 18 over 18 to 30 EM837050 5.0 .1969 6 15 60 1°

5.0

EM837907

15

60

2°

.1969

6

h10 — 40 0 — 48 0 — 58 0 — 70 0 — 84 0 EM837908 5.0 .1969 6 15 60 3°

0 0 0 0 0

h6 — 6 — 8 — 9 — 11 — 13 EM837917 6.0 .2362 6 20 60 30´

EM837060 6.0 .2362 6 20 60 1°

EM837909 6.0 .2362 6 20 60 2°

EM837910 6.0 .2362 8 20 65 3°

EM837918 8.0 .3150 8 25 70 30´

EM837080 8.0 .3150 8 25 70 1°

EM837911 8.0 .3150 8 25 70 2°

EM837912 8.0 .3150 10 25 75 3°

▶We can supply various sizes and taper angles.

Mill Dia. Shank Dia. Taper Angle

Tolerance(mm) Tolerance Tolerance

0~-0.03 h6 ±5´

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Iron

Steels

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○

908 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 909