Page 912 - YG 2019

P. 912

X-POWER X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

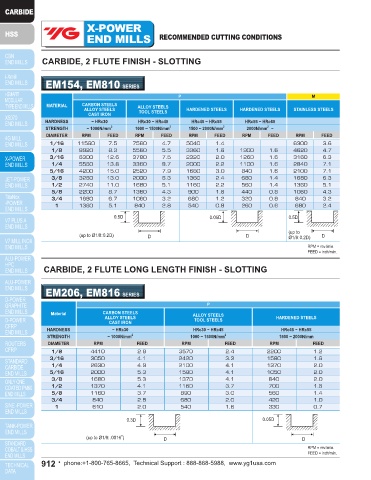

CARBIDE, 2 FLUTE FINISH - SLOTTING CARBIDE, 4 FLUTE FINISH - SIDE CUTTING

EM154, EM810 SERIES EM153, EM811 SERIES

P M P M

MATERIAL CARBON STEELS ALLOY STEELS MATERIAL CARBON STEELS ALLOY STEELS

ALLOY STEELS TOOL STEELS HARDENED STEELS HARDENED STEELS STAINLESS STEELS ALLOY STEELS TOOL STEELS HARDENED STEELS HARDENED STEELS STAINLESS STEELS

CAST IRON CAST IRON

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65 HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~ STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

1/16 11560 7.5 7560 4.7 5040 1.4 6300 3.6 1/16 11560 11.0 7560 6.7 5040 2.0 6300 5.5

1/8 8920 8.3 5560 5.5 3360 1.6 1900 1.6 4620 4.7 1/8 8920 12.6 5560 7.9 3360 2.4 1900 2.4 4620 6.7

3/16 6300 12.6 3780 7.5 2320 2.0 1260 1.6 3160 6.3 3/16 6300 23.6 3780 14.2 2320 2.8 1260 2.4 3160 11.8

1/4 5560 13.8 3360 8.7 2000 2.2 1100 1.6 2840 7.1 1/4 5560 26.0 3360 16.2 2000 3.2 1100 2.4 2840 13.0

5/16 4200 15.0 2520 7.9 1680 3.0 840 1.6 2100 7.1 5/16 4200 28.0 2520 15.0 1680 4.3 840 2.4 2100 13.8

3/8 3260 13.0 2000 6.3 1360 2.4 680 1.4 1680 6.3 3/8 3260 24.0 2000 11.8 1360 3.6 680 2.0 1680 11.8

1/2 2740 11.0 1680 5.1 1160 2.2 560 1.4 1360 5.1 1/2 2740 20.5 1680 9.9 1160 3.2 560 2.0 1360 9.5

5/8 2200 8.7 1360 4.3 900 1.6 440 0.8 1060 4.3 5/8 2200 16.2 1360 7.9 900 2.4 440 1.2 1060 7.9

3/4 1680 6.7 1060 3.2 680 1.2 320 0.8 840 3.2 3/4 1680 12.6 1060 6.3 680 1.6 320 1.2 840 5.9

1 1360 5.1 840 2.8 540 0.8 260 0.6 680 2.4 1 1360 9.9 840 5.1 540 1.2 260 0.8 680 4.7

0.5D 0.05D 0.5D

1.0D

(up to 0.05D

(up to Ø1/8:0.2D) D D Ø1/8:0.2D) D

RPM = rev./min. RPM = rev./min.

FEED = inch/min. FEED = inch/min.

CARBIDE, 2 FLUTE LONG LENGTH FINISH - SLOTTING CARBIDE, 4 FLUTE LONG LENGTH FINISH - SIDE CUTTING

EM206, EM816 SERIES EM207, EM817 SERIES

P P

Material CARBON STEELS ALLOY STEELS MATERIAL CARBON STEELS ALLOY STEELS

ALLOY STEELS TOOL STEELS HARDENED STEELS ALLOY STEELS TOOL STEELS HARDENED STEELS HARDENED STEELS

CAST IRON CAST IRON

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED

1/8 4410 2.8 3570 2.4 2200 1.2 1/8 4410 4.5 3570 3.9 2200 2.2 1890 1.2

3/16 3050 4.1 2420 3.3 1580 1.6 3/16 3050 7.1 2420 5.5 1580 2.8 1260 1.6

1/4 2630 4.9 2100 4.1 1370 2.0 1/4 2630 8.5 2100 7.1 1370 3.5 1160 2.0

5/16 2000 5.3 1580 4.1 1050 2.0 5/16 2000 9.1 1580 7.1 1050 3.5 840 2.0

3/8 1680 5.3 1370 4.1 840 2.0 3/8 1680 9.1 1370 7.1 840 3.5 670 2.0

1/2 1370 4.1 1160 3.7 700 1.6 1/2 1370 7.1 1160 6.3 700 2.8 560 1.6

5/8 1160 3.7 890 3.0 560 1.4 5/8 1160 6.3 890 4.9 560 2.4 440 1.4

3/4 840 2.8 680 2.0 420 1.0 3/4 840 4.5 680 3.5 420 1.8 340 1.0

1 610 2.0 540 1.6 330 0.7 1 670 4.5 540 3.5 340 1.8 270 1.0

0.3D 0.05D

2.5D 2.0D

0.05D 0.02D

(up to Ø1/8:.0016") D D

RPM = rev./min. RPM = rev./min.

FEED = inch/min. FEED = inch/min.

912 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 913