Page 935 - YG 2019

P. 935

X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS

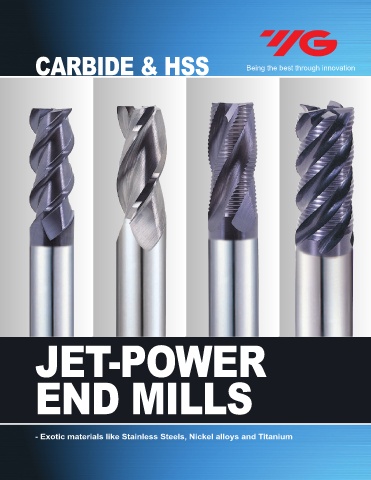

CARBIDE & HSS Being the best through innovation

CARBIDE, 4 FLUTE STUB CORNER RADIUS - SIDE CUTTING

EM839 SERIES

P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS

CAST IRON STEELS

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED

2.0 13870 13.4 9070 8.1 6050 2.4

2.5 12290 14.2 7870 8.7 5040 2.6

3.0 10700 15.2 6670 9.5 4030 2.8 2280 2.8

3.5 9890 21.1 6100 13.0 3780 2.8 2030 2.8

4.0 9070 27.0 5540 16.5 3530 2.8 1780 2.8

5.0 7560 28.4 4540 16.9 2780 3.4 1510 2.8

6.0 6670 31.1 4030 19.3 2400 3.7 1320 2.8

8.0 5040 33.5 3020 17.9 2020 5.1 1010 2.8

10.0 3910 28.7 2400 14.2 1630 4.3 820 2.4

12.0 3290 24.6 2020 11.8 1390 3.7 670 2.4

16.0 2640 19.3 1630 9.5 1080 2.8 530 1.4

1.0D

0.05D

RPM = rev./min.

FEED = inch/min.

CARBIDE, 6 FLUTE STUB CORNER RADIUS - SIDE CUTTING

EM897 SERIES

P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS

CAST IRON STEELS

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED JET-POWER

6.0 6670 31.1 4030 19.3 2400 3.7 1320 2.8

8.0 5040 33.5 3020 17.9 2020 5.1 1010 2.8

10.0 3910 28.7 2400 14.2 1630 4.3 820 2.4

12.0 3290 24.6 2020 11.8 1390 3.7 670 2.4

1.0D END MILLS

0.05D

RPM = rev./min.

FEED = inch/min.

- Exotic materials like Stainless Steels, Nickel alloys and Titanium

934 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com