Page 953 - YG 2019

P. 953

JET-POWER JET-POWER

END MILLS EH921 SERIES PLAIN SHANK END MILLS RECOMMENDED CUTTING CONDITIONS

CARBIDE, MULTI FLUTE 45° HELIX LONG REACH

FINE PITCH ROUGHING CARBIDE, 3&4 FLUTE FINISH - SLOTTING

▶Suitable for low hardness materials (under HRc45), alloy steels, tool steels, carbon steels, prehardened steels, stainless steel, titanium, inconel,

nimonic, etc.

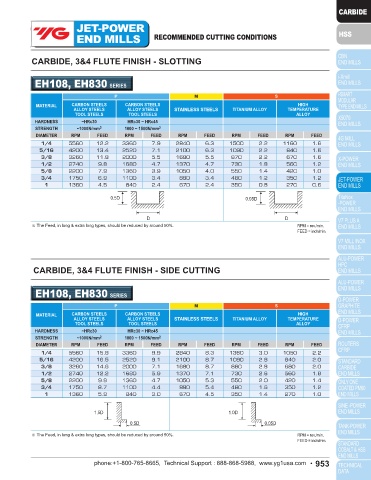

▶High chip removed and minimizing breakages of cutting edges. EH108, EH830 SERIES

▶Corner Protection against chipping.

P M S

D3 MATERIAL CARBON STEELS CARBON STEELS HIGH

ALLOY STEELS ALLOY STEELS STAINLESS STEELS TITANIUM ALLOY TEMPERATURE

TOOL STEELS TOOL STEELS ALLOY

D2 D1

HARDNESS ~HRc30 HRc30 ~ HRc45

L1 STRENGTH ~1000N/mm 2 1000 ~ 1500N/mm 2

L3 DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

L2 1/4 5560 12.2 3360 7.9 2840 6.3 1500 2.2 1160 1.6

5/16 4200 13.4 2520 7.1 2100 6.3 1090 2.2 840 1.6

3/8 3260 11.8 2000 5.5 1680 5.5 870 2.2 670 1.6

1/2 2740 9.8 1680 4.7 1370 4.7 730 1.8 560 1.2

5/8 2200 7.9 1360 3.9 1050 4.0 550 1.4 420 1.0

P.955 ◇ Call for Availability 3/4 1750 6.9 1100 3.4 880 3.4 480 1.2 350 1.2

1 1360 4.5 840 2.4 670 2.4 350 0.8 270 0.6

Unit : mm

Mill Diameter Shank Length Length Overall Neck 0.5D 0.05D

EDP No. Metric Inch Diameter of Cut Below Shank Length Diameter No. of

Flute

D1 D2 L1 L3 L2 D3

D D

EH921060 6.0 .2362 6 16 20 57 5.5 4

EH921080 8.0 .3150 8 16 26 63 7.5 4 ※ The Feed, in long & extra long types, should be reduced by around 50%. RPM = rev./min.

FEED = inch/min.

EH921100 10.0 .3937 10 22 31 72 9.5 4

EH921120 12.0 .4724 12 26 37 83 11.5 4

EH921160 16.0 .6299 16 32 51 100 15.5 5

EH921200 20.0 .7874 20 38 59 110 19.2 6

Tolerances according to DIN 7160 & 7161 CARBIDE, 3&4 FLUTE FINISH - SIDE CUTTING

Tolerance range in µm

Nominal-Diameter in mm

from 1 to 3 over 3 to 6 over 6 to 10 over 10 to 18 over 18 to 30 EH108, EH830 SERIES

h10 — 40 0 — 48 0 — 58 0 — 70 0 — 84 0 P M S

0

0

h6 — 6 0 0 0 — 11 — 13

— 9

— 8

Enforced cutting edge MATERIAL CARBON STEELS CARBON STEELS HIGH

ALLOY STEELS ALLOY STEELS STAINLESS STEELS TITANIUM ALLOY TEMPERATURE

TOOL STEELS TOOL STEELS ALLOY

HARDNESS ~HRc30 HRc30 ~ HRc45

STRENGTH ~1000N/mm 2 1000 ~ 1500N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

1/4 5560 15.8 3360 9.9 2840 8.3 1360 3.0 1050 2.2

5/16 4200 16.5 2520 9.1 2100 8.7 1090 2.8 840 2.0

3/8 3260 14.6 2000 7.1 1680 8.7 880 2.8 680 2.0

1/2 2740 12.2 1680 5.9 1370 7.1 730 2.6 560 1.8

5/8 2200 9.9 1360 4.7 1050 5.3 550 2.0 420 1.4

3/4 1750 8.7 1100 4.4 880 5.4 480 1.6 350 1.2

1 1360 5.9 840 3.0 670 4.5 350 1.4 270 1.0

1.5D 1.0D

◎ : Excellent ◯ : Good

P H M K N S 0.5D 0.05D

Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature ※ The Feed, in long & extra long types, should be reduced by around 50%. RPM = rev./min.

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy FEED = inch/min.

○ ◎ ◎ ○ ◎ ◎ ○

952 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 953