Page 230 - Robot Design Handbook ROBOCON Malaysia 2019

P. 230

which sucks air from the atmosphere is stored in a high pressure tank called receiver. This

compressed air is then supplied to the system through a series of solenoid valves. Each valve

is then plumbed to a cylinder. This allows the distribution of power from the engine to the

equipment. The total maximum pressure pump is 0.6 MPa. The force is equaled to the area

of the cylinder piston times the pressure. The valves need a minimum of 0.15 MPa to 0.7

MPa to work properly. There are three small cylinders and one big cylinder of 0.7 MPa and

0.8 MPa max pressure respectively. These three cylinders are functioning to extend and pull

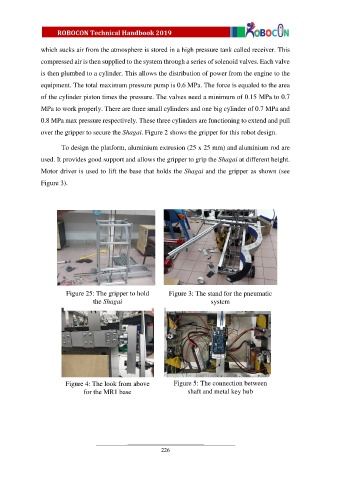

over the gripper to secure the Shagai. Figure 2 shows the gripper for this robot design.

To design the platform, aluminium extrusion (25 x 25 mm) and aluminium rod are

used. It provides good support and allows the gripper to grip the Shagai at different height.

Motor driver is used to lift the base that holds the Shagai and the gripper as shown (see

Figure 3).

Figure 25: The gripper to hold Figure 3: The stand for the pneumatic

the Shagai system

Figure 4: The look from above Figure 5: The connection between

for the MR1 base shaft and metal key hub

226