Page 85 - JKR HEALTH FACILITY ARCHITECTURAL NEEDS STATEMENT 2021 EDITION_Neat

P. 85

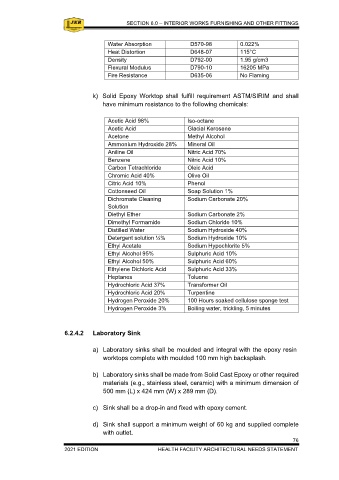

SECTION 6.0 – INTERIOR WORKS FURNISHING AND OTHER FITTINGS SECTION 6.0 – INTERIOR WORKS FURNISHING AND OTHER FITTINGS

Water Absorption D570-98 0.022%

Heat Distortion D648-07 115°C e) If required, marine edge can be applied to the worktop at the sink

Density D792-00 1.95 g/cm3 location to prevent unwanted spills.

Flexural Modulus D790-10 16205 MPa

Fire Resistance D635-06 No Flaming f) Sink shall be complete with polypropylene piping and connection to a

chemical-resistant black polypropylene anti-siphon bottle trap or dilution

k) Solid Epoxy Worktop shall fulfill requirement ASTM/SIRIM and shall recovery trap. The type of waste trap is to be discussed during the

have minimum resistance to the following chemicals: interaction.

Acetic Acid 98% Iso-octane

Acetic Acid Glacial Kerosene 6.2.4.3 Laboratory Caseworks

Acetone Methyl Alcohol

Ammonium Hydroxide 28% Mineral Oil a) The cabinet shall comprise of base cabinet, drawer and shelf as follows:

Aniline Oil Nitric Acid 70% i. Base cabinet shall be a 0.8 mm thick electro-galvanised steel

Benzene Nitric Acid 10% sheet with a double-layered wall, including top and bottom

Carbon Tetrachloride Oleic Acid panel.

Chromic Acid 40% Olive Oil

Citric Acid 10% Phenol ii. Drawer shall be a 0.8 mm thick electro-galvanised steel sheet

Cottonseed Oil Soap Solution 1% with concealed drawer guide and load-bearing capacity of 1.5

Dichromate Cleaning Sodium Carbonate 20% kg.

Solution

Diethyl Ether Sodium Carbonate 2%

Dimethyl Formamide Sodium Chloride 10% iii. The drawer and based cabinet below the worktop shall be on a

Distilled Water Sodium Hydroxide 40% roller track for easy slide and maintenance, where required,

Detergent solution ¼% Sodium Hydroxide 10% such as pathology lab, stat lab, etc.

Ethyl Acetate Sodium Hypochlorite 5%

Ethyl Alcohol 95% Sulphuric Acid 10% iv. Shelf shall be a 0.8 mm thick electro-galvanised steel sheet.

Ethyl Alcohol 50% Sulphuric Acid 60%

Ethylene Dichloric Acid Sulphuric Acid 33% b) Specialists shall locally manufacture all laboratory bench system. The

Heptanes Toluene system shall consist of oven-baked epoxy powder-coated electro-

Hydrochloric Acid 37% Transformer Oil galvanised steel frames with shelves and cabinets made of oven-baked

Hydrochloric Acid 20% Turpentine epoxy powder-coated electro-galvanised steel sheets.

Hydrogen Peroxide 20% 100 Hours soaked cellulose sponge test

Hydrogen Peroxide 3% Boiling water, trickling, 5 minutes c) Powder coating shall be from an approved brand with low VOC and

anti-microbial properties. The certificate must be presented during

submission and interaction.

6.2.4.2 Laboratory Sink

d) The frame shall be made of a cantilevered system designed of 200 mm

a) Laboratory sinks shall be moulded and integral with the epoxy resin off the finished floor level to make under bench cleaning hassle-free and

worktops complete with moulded 100 mm high backsplash. be able to withstand heavy load without compromising safety or

otherwise stated.

b) Laboratory sinks shall be made from Solid Cast Epoxy or other required

materials (e.g., stainless steel, ceramic) with a minimum dimension of e) The whole laboratory bench system’s height shall be 900 mm high for

500 mm (L) x 424 mm (W) x 289 mm (D). standing and 750 mm high for seating.

c) Sink shall be a drop-in and fixed with epoxy cement. f) The cabinets are to be flush face construction, with doors and drawers

in the same plane as the cabinet face frame, without overlap.

d) Sink shall support a minimum weight of 60 kg and supplied complete

with outlet.

76 77

2021 EDITION HEALTH FACILITY ARCHITECTURAL NEEDS STATEMENT 2021 EDITION HEALTH FACILITY ARCHITECTURAL NEEDS STATEMENT