Page 76 - BE Mech Curriculum and Syllabus - R2017 - REC

P. 76

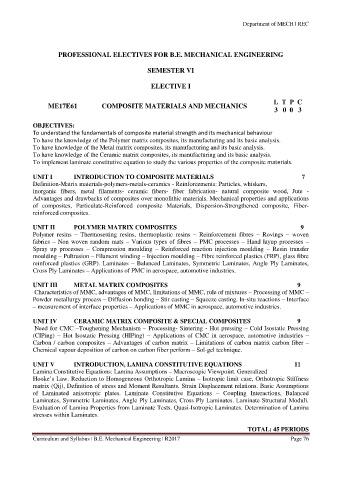

Department of MECH | REC

PROFESSIONAL ELECTIVES FOR B.E. MECHANICAL ENGINEERING

SEMESTER VI

ELECTIVE I

L T P C

ME17E61 COMPOSITE MATERIALS AND MECHANICS

3 0 0 3

OBJECTIVES:

To understand the fundamentals of composite material strength and its mechanical behaviour

To have the knowledge of the Polymer matrix composites, its manufacturing and its basic analysis.

To have knowledge of the Metal matrix composites, its manufacturing and its basic analysis.

To have knowledge of the Ceramic matrix composites, its manufacturing and its basic analysis.

To implement laminate constitutive equation to study the various properties of the composite materials.

UNIT I INTRODUCTION TO COMPOSITE MATERIALS 7

Definition-Matrix materials-polymers-metals-ceramics - Reinforcements: Particles, whiskers,

inorganic fibers, metal filaments- ceramic fibers- fiber fabrication- natural composite wood, Jute -

Advantages and drawbacks of composites over monolithic materials. Mechanical properties and applications

of composites, Particulate-Reinforced composite Materials, Dispersion-Strengthened composite, Fiber-

reinforced composites.

UNIT II POLYMER MATRIX COMPOSITES 9

Polymer resins – Thermosetting resins, thermoplastic resins – Reinforcement fibres – Rovings – woven

fabrics – Non woven random mats – Various types of fibres – PMC processes – Hand layup processes –

Spray up processes – Compression moulding – Reinforced reaction injection moulding – Resin transfer

moulding – Pultrusion – Filament winding – Injection moulding – Fibre reinforced plastics (FRP), glass fibre

reinforced plastics (GRP). Laminates – Balanced Laminates, Symmetric Laminates, Angle Ply Laminates,

Cross Ply Laminates – Applications of PMC in aerospace, automotive industries.

UNIT III METAL MATRIX COMPOSITES 9

Characteristics of MMC, advantages of MMC, limitations of MMC, rule of mixtures – Processing of MMC –

Powder metallurgy process – Diffusion bonding – Stir casting – Squeeze casting. In-situ reactions – Interface

– measurement of interface properties – Applications of MMC in aerospace, automotive industries.

UNIT IV CERAMIC MATRIX COMPOSITE & SPECIAL COMPOSITES 9

Need for CMC –Toughening Mechanism – Processing- Sintering - Hot pressing – Cold Isostatic Pressing

(CIPing) – Hot Isostatic Pressing (HIPing) – Applications of CMC in aerospace, automotive industries –

Carbon / carbon composites – Advantages of carbon matrix – Limitations of carbon matrix carbon fiber –

Chemical vapour deposition of carbon on carbon fiber perform – Sol-gel technique.

UNIT V INTRODUCTION, LAMINA CONSTITUTIVE EQUATIONS 11

Lamina Constitutive Equations: Lamina Assumptions – Macroscopic Viewpoint. Generalized

Hooke’s Law. Reduction to Homogeneous Orthotropic Lamina – Isotropic limit case, Orthotropic Stiffness

matrix (Qij), Definition of stress and Moment Resultants. Strain Displacement relations. Basic Assumptions

of Laminated anisotropic plates. Laminate Constitutive Equations – Coupling Interactions, Balanced

Laminates, Symmetric Laminates, Angle Ply Laminates, Cross Ply Laminates. Laminate Structural Moduli.

Evaluation of Lamina Properties from Laminate Tests. Quasi-Isotropic Laminates. Determination of Lamina

stresses within Laminates.

TOTAL: 45 PERIODS

Curriculum and Syllabus | B.E. Mechanical Engineering | R2017 Page 76