Page 71 - BE Mech Curriculum and Syllabus - R2017 - REC

P. 71

Department of MECH | REC

2. Logan, D.L., “A first course in Finite Element Method”, Thomson Asia Pvt. Ltd., 2002

REFERENCES:

1. Reddy. J.N., “An Introduction to the Finite Element Method”, 3rd Edition, Tata McGraw

Hill, 2005

2. Rao, S.S., “The Finite Element Method in Engineering”, 3rd Edition, Butterworth Heinemann, 2004

3. Robert D. Cook, David S. Malkus, Michael E. Plesha, Robert J. Witt, “Concepts and Applications of

Finite Element Analysis”, 4th Edition, Wiley Student Edition, 2002.

4. Chandrupatla & Belagundu, “Introduction to Finite Elements in Engineering”, 3rd Edition, Prentice

Hall College Div, 1990

5. Bhatti Asghar M, "Fundamental Finite Element Analysis and Applications", John Wiley & Sons,

2005 (Indian Reprint 2013)

6. David Hutton, “Fundamentals of Finite Element Analysis” McGrawHill, 2005

L T P C

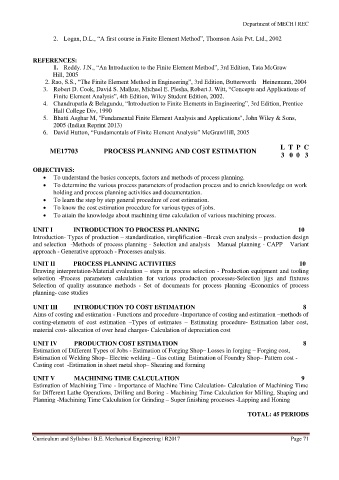

ME17703 PROCESS PLANNING AND COST ESTIMATION

3 0 0 3

OBJECTIVES:

To understand the basics concepts, factors and methods of process planning.

To determine the various process parameters of production process and to enrich knowledge on work

holding and process planning activities and documentation.

To learn the step by step general procedure of cost estimation.

To know the cost estimation procedure for various types of jobs.

To attain the knowledge about machining time calculation of various machining process.

UNIT I INTRODUCTION TO PROCESS PLANNING 10

Introduction- Types of production – standardization, simplification –Break even analysis – production design

and selection -Methods of process planning - Selection and analysis – Manual planning - CAPP – Variant

approach - Generative approach - Processes analysis.

UNIT II PROCESS PLANNING ACTIVITIES 10

Drawing interpretation-Material evaluation – steps in process selection - Production equipment and tooling

selection -Process parameters calculation for various production processes-Selection jigs and fixtures

Selection of quality assurance methods - Set of documents for process planning -Economics of process

planning- case studies

UNIT III INTRODUCTION TO COST ESTIMATION 8

Aims of costing and estimation - Functions and procedure -Importance of costing and estimation –methods of

costing-elements of cost estimation –Types of estimates – Estimating procedure- Estimation labor cost,

material cost- allocation of over head charges- Calculation of depreciation cost

UNIT IV PRODUCTION COST ESTIMATION 8

Estimation of Different Types of Jobs - Estimation of Forging Shop– Losses in forging – Forging cost,

Estimation of Welding Shop– Electric welding – Gas cutting Estimation of Foundry Shop– Pattern cost -

Casting cost -Estimation in sheet metal shop– Shearing and forming

UNIT V MACHINING TIME CALCULATION 9

Estimation of Machining Time - Importance of Machine Time Calculation- Calculation of Machining Time

for Different Lathe Operations, Drilling and Boring - Machining Time Calculation for Milling, Shaping and

Planning -Machining Time Calculation for Grinding – Super finishing processes -Lapping and Honing

TOTAL: 45 PERIODS

Curriculum and Syllabus | B.E. Mechanical Engineering | R2017 Page 71