Page 319 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 319

Chapter 5 Cold water systems

Both valves are manufactured from DZR resistant brass and have either type A

compression fittings or female BSP threads for connection to the pipework. The

valves should conform to BS 6282 Part 1 for use in hot or cold water systems

up to 90°C.

In domestic premises the risk from fluid category 2 generally occurs where the

hot and cold supplies are taken to a single terminal fitting such as mixer taps

or shower valves. This is known as a cross-connection. However, care must be

taken when installing single check valves to hot water supplies as the expansion

of the water can cause excessive pressure on the check valve causing it to fail.

Other uses include the cold water connections to drinks machines.

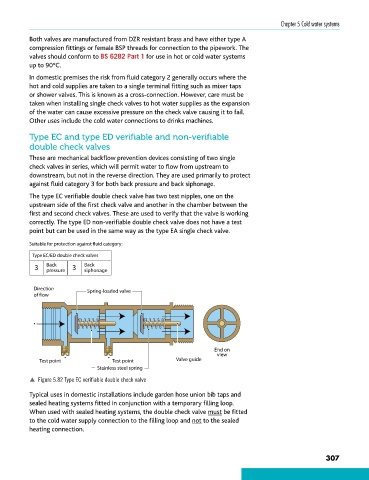

Type EC and type ED verifiable and non-verifiable

double check valves

These are mechanical backflow prevention devices consisting of two single

check valves in series, which will permit water to flow from upstream to

downstream, but not in the reverse direction. They are used primarily to protect

against fluid category 3 for both back pressure and back siphonage.

The type EC verifiable double check valve has two test nipples, one on the

upstream side of the first check valve and another in the chamber between the

first and second check valves. These are used to verify that the valve is working

correctly. The type ED non-verifiable double check valve does not have a test

point but can be used in the same way as the type EA single check valve.

Suitable for protection against fluid category:

Type EC/ED double check valves

3 Back 3 Back

siphonage

pressure

Direction Spring-loaded valve

of flow

End on

view

Test point Test point Valve guide

Stainless steel spring

p Figure 5.82 Type EC verifiable double check valve

Typical uses in domestic installations include garden hose union bib taps and

sealed heating systems fitted in conjunction with a temporary filling loop.

When used with sealed heating systems, the double check valve must be fitted

to the cold water supply connection to the filling loop and not to the sealed

heating connection.

307

9781510416482.indb 307 29/03/19 8:58 PM