Page 507 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 507

Chapter 7 Central heating systems

Hot water

cylinder

Ground source Two-way

heat pump manifold

Pump Pump

Buried captor or ‘slinky’ 4

2 3 5 6

1 7

Pump Top view

Underfloor heating circuits

The flow and return connections to

the thermostatic mixing valves enter

side by side

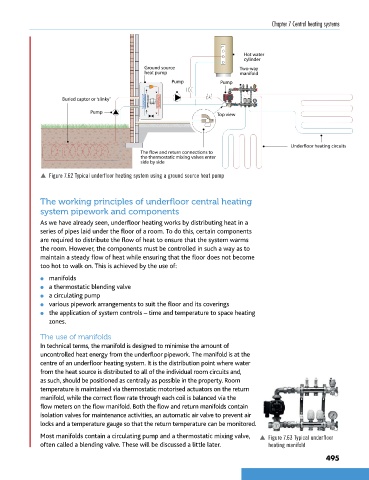

p Figure 7.62 Typical underfloor heating system using a ground source heat pump

The working principles of underfloor central heating

system pipework and components

As we have already seen, underfloor heating works by distributing heat in a

series of pipes laid under the floor of a room. To do this, certain components

are required to distribute the flow of heat to ensure that the system warms

the room. However, the components must be controlled in such a way as to

maintain a steady flow of heat while ensuring that the floor does not become

too hot to walk on. This is achieved by the use of:

l manifolds

l a thermostatic blending valve

l a circulating pump

l various pipework arrangements to suit the floor and its coverings

l the application of system controls – time and temperature to space heating

zones.

The use of manifolds

In technical terms, the manifold is designed to minimise the amount of

uncontrolled heat energy from the underfloor pipework. The manifold is at the

centre of an underfloor heating system. It is the distribution point where water

from the heat source is distributed to all of the individual room circuits and,

as such, should be positioned as centrally as possible in the property. Room

temperature is maintained via thermostatic motorised actuators on the return

manifold, while the correct flow rate through each coil is balanced via the

flow meters on the flow manifold. Both the flow and return manifolds contain

isolation valves for maintenance activities, an automatic air valve to prevent air

locks and a temperature gauge so that the return temperature can be monitored.

Most manifolds contain a circulating pump and a thermostatic mixing valve, p Figure 7.63 Typical underfloor

often called a blending valve. These will be discussed a little later. heating manifold

495

9781510416482.indb 495 29/03/19 9:03 PM