Page 619 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 619

Chapter 9 Sanitation systems

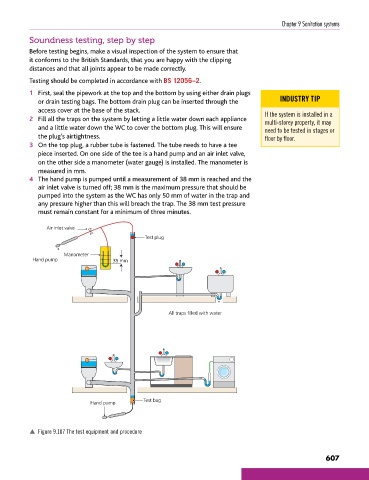

Soundness testing, step by step

Before testing begins, make a visual inspection of the system to ensure that

it conforms to the British Standards, that you are happy with the clipping

distances and that all joints appear to be made correctly.

Testing should be completed in accordance with BS 12056–2.

1 First, seal the pipework at the top and the bottom by using either drain plugs

or drain testing bags. The bottom drain plug can be inserted through the INDUSTRY TIP

access cover at the base of the stack. If the system is installed in a

2 Fill all the traps on the system by letting a little water down each appliance multi-storey property, it may

and a little water down the WC to cover the bottom plug. This will ensure need to be tested in stages or

the plug’s airtightness. floor by floor.

3 On the top plug, a rubber tube is fastened. The tube needs to have a tee

piece inserted. On one side of the tee is a hand pump and an air inlet valve,

on the other side a manometer (water gauge) is installed. The manometer is

measured in mm.

4 The hand pump is pumped until a measurement of 38 mm is reached and the

air inlet valve is turned off; 38 mm is the maximum pressure that should be

pumped into the system as the WC has only 50 mm of water in the trap and

any pressure higher than this will breach the trap. The 38 mm test pressure

must remain constant for a minimum of three minutes.

Air inlet valve

Test plug

Manometer

Hand pump 38 mm

All traps filled with water

Test bag

Hand pump

p Figure 9.107 The test equipment and procedure

607

9781510416482.indb 607 29/03/19 9:08 PM