Page 190 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 190

O SECURE LUBRICATION

Liquid from the casing flows between

the rear casing and the magnet lining

which prevents clogging. The fluid is

then forced to flow to the rear bushing

then through the shaft to the front

bushing. This flow guarantees perfect

lubrication for the bushing.

G) LONG LIFE THRUST RING

The thrust ring is connected to the

magnet not to the impeller, which

reduces its rotating velocity. The )>

lower velocity Increases the life "O

"Q.

of the thrust ring. 16"

a.

"ti

9 NO ADHESIVE :...------ a

0

All of the bushings as well as the liner lR

ring and thrust ring are not attached by (/)

adhesives. Thus the parts are easily 0

(D

replaced and the parts are free from co·

(/)

any weakness of the adhesive. ::::,

o'

....

o

:::r

(D

3

s:

!!!..

Ill

::::,

a.

"ti

�

Standard materials: other materials available depei ldent upon application. a

0

No. Part Name Material :::r

(D

3

1 Liner Ring Carbon-filled PTFE er

2 Impeller PVDF (KYNAR) •• !!!..

"ti

3 casing PVDF (KYNAR) -

�

4 Bushing Plate PVDF (KYNAR) (/)

5 Front Bushing Carbon-filled PTFE

6 Thrust Ring CERAMIC

7 RearCasing Carbon-filled PVDF

8 OUter Magnet

9 Inner Magnet

10 Shah CERAMIC

11 Rear Bushing Carbon-filled PTFE

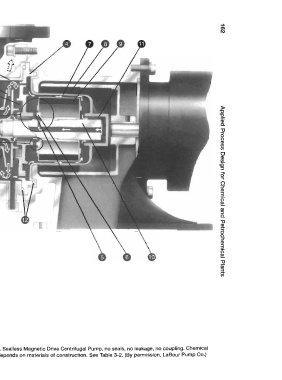

12 ·o· Ring VITON Figure 3-1A. Sealless Magnetic Drive Centrifugal Pump, no seals, no leakage, no coupling. Chemical

''Ky,wlsa,.--ol....._Cc,p. resistance depends on materials of construction. See Table 3-2. (By pennission, LaBour Pump Co.)