Page 194 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 194

Pumping of Liquids 165

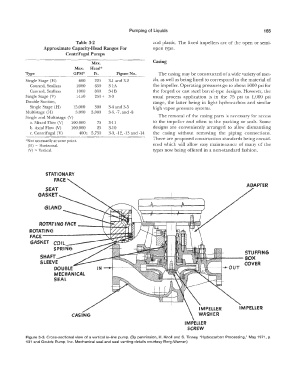

Table 3-2 and plastic. The lined impellers are of the open or semi-

Approximate Capacity-Head Ranges For open type.

Centrifugal Pumps

=-- - ----=---··===-- - ����--=::.._ ::-----.c_ - ===---==---

Max. Casing

Max. Head*

Type GPM* Ft. Figure No. The casing may be constructed of a wide variety of met-

--------------------------

Single Stage (H) 600 225 3-1 and 3-2 als, as well as being lined to correspond to the material of

Canned, Sealless 2000 650 3-lA the impeller. Operating pressures go to about 5000 psi for

Canned, Sealless !000 800 3-IB the forged or cast steel barrel-type designs. However, the

Single Stage (V) >L:jO 250+ 3-3 usual process application is in the 75 psi to 1,000 psi

Double Suction, range, the latter being in light hydrocarbon and similar

Single Stage (H) 15,000 300 34 and 3-5 high vapor pressure systems.

Multistage (H) 3,000 5,000 3-6, -7, and -8

Single and Multistage (V) The removal of the casing parts is necessary for access

a. Mixed Flow CV) 100,000 75 3-11 Lo the impeller and often to the packing or seals. Some

b. Axial Flow (V) 100,000 25 3-10 designs are conveniently arranged to allow dismantling

c. Centrifugal (V) 400± 5,750 3-9, -12, -13 and -14 the casing without removing the piping connections.

There are proposed construction standards being consid-

''Not necessarily at same point.

(I-I) = Horizontal. ered which will allow easy maintenance of many of the

(V) = Vertical. t>ves now being offered in a non-standard fashion.

STATIONARY

FACE

SEAT

GASKET

-

GLAND

ROTATING

FACE���--�----�.-.:��'7':t

GASKET COIL ·-

SPRI �

SHAFT_.--

SLEEVE

DOUBLE

MECHANICAL

SEAL.

IMPELLER

SCREW

Figure 3-3. Cross-sectional view of a vertical in-line pump. (By permission, H. Knoll and S. Tinney, "Hydrocarbon Processing," May 1971, p.

131 and Goulds Pump, Inc. Mechanical seal and seal venting details courtesy Borg-Warner.)