Page 193 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 193

164 Applied Process Design for Chemical and Petrochemical Plants

Heavy Duly Volule Confined Type Gaskel

(150,300 lb. Slul

and 125 lb. Casi Iron) Quench Type Gland (Opliona I Conslruclionl

Wear Rings (Hardened

Malerials Oplionall

Seal Lanlern

Enclosed Type

Impeller i

Hydraulically

Balanced far

Reduced Thrust

Load Slinger; La byrinlh Type

Ven! and Drain (Optional) Back Plate; Water ·Caoled Type,Extra Deep Stuffing Box

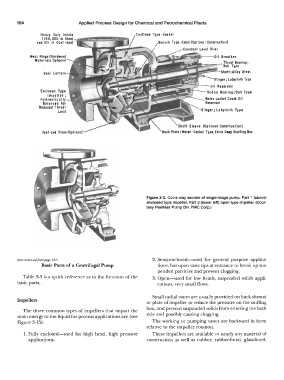

Figure 3-2. Cut-a-way section of single-stage pump. Part 1 (above)

enclosed type impeller, Part 2 (lower left) open type impeller. (Cour-

tesy Peerless Pump Div. FMC Corp.)

(text rm1ti11uedfrompage Jf,I) 2. Semi-enclosed-used for general purpose applica-

Basic Parts of a Centrifugal Pump tions, has open vane tips at entrance to break up sus-

pended particles and prevent clogging.

Table 3-3 is a quick reference as to the function of the 3. Open-used for low heads, suspended solids appli-

basic parts. cations, very small flows.

Small radial vanes are usually provided on back shroud

Impellers or plate of impeller to reduce the pressure on the stuffing

The three common types of impellers that impart the box, and prevent suspended solids from entering the back

main energy to the liquid for process applications are (see side and possibly causing clogging.

Figure 3-15): The working or pumping vanes are backward in form

relative to the impeller rotation.

1. Fully enclosed-used for high head, high pressure These impellers are available in nearly any material of

applications. construction as well as rubber, rubber-lined, glass-lined,