Page 214 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 214

184 Applied Process Design for Chemical and Petrochemical Plants

-c:,

..

Atmospheric "" ...

Pressure ::c: Exit Loss

� I ;::

I

""

Suction Di.scharge iii D

..

I

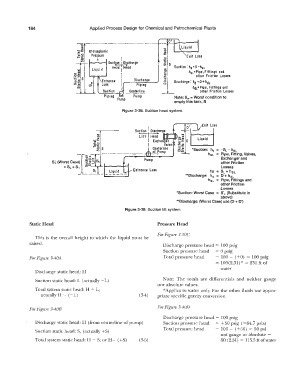

Liquid Head Head ... Suction: h5 =S-hsL

�

hSL =Pipe, Fittings and

..

I s:; of her Friction Losses

Entrance I O_ i s_c_h_ a r..,_g_ e _..., u

Loss I Piping Cl Discharge: hd =D+hdL

I hdL =Pipe, Fittings and

Suction -·-·- other Friction Losses

Centerline

Piping Pump Note: Sw = Worst condition to

Pump

empty this tank, ft

Figure 3-38. Suction head system.

Exit Loss

0

1

"" ..

� .. �,M

-c:,

-::c:

o:;:

i,;;.� s s=u

a;;

�·.;:

U) *Suction: h. = -SL - hsL

hsL = Pipe, Fitting, Valves,

Exchanger and

other Friction

Losses

-hs = SL+ hsL

**Discharge: hd = D + hdL

hdL = Pipe, Fittings and

other Friction

Losses

*Suction: Worst Case = S' L (Substitute in

above)

**Discharge: (Worst Case) use (D + D1

Figure 3-39. Suction lift system

Static Head Pressure Head

For Figure 3-40C

This is the overall height to which the liquid must be

raised.

Discharge pressure head = 100 psig

Suction pressure head = 0 psig

For Figure 3-40A Total pressure head = 100 - ( +O) = 100 psig

= 100(2.31)* = 231 ft of

water

Discharge static head: H

Suction static head: L (actually - L) Note: The totals are differentials and neither gauge

nor absolute values.

Total system static head: H + L; *Applies to water only. For the other fluids use appro-

actually H -- (- L) (3-4) priate specific gravity conversion.

For Figure 3-40D

For Figure 3-40B

Discharge pressure head= 100 psig

Discharge static head: I-I (from centerline of pump) Suction pressure head = + 50 psig ( =64. 7 psia)

Total pressure head = 100 - ( +50) = 50 psi

Suction static head: S, (actually +S)

not gauge or absolute =

Total system static head: 1-1 - S; or H- ( +S) (3-5) 50 (2.31) = 115.Sftofwater