Page 270 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 270

240 Applied Process Design for Chemical and Petrochemical Plants

for assumed spherical particles in a surfactant-free system The minimum residence time as determined by

[26]. The minimum particle diameter for many fine dis- Stokes' Law terminal settling velocity is:

persions is 100 microns; however, Reference [28] has

reviewed a wide variety of liquid drop data and suggests

that a good choice is 150 micron or 0.15 cm or 0.0005 ft. tmin = b /v., min (4-17)

This is also the particle size used in the API Design Manu-

al [24]. Using too large an assumed particle diameter will he = height of segment of circle, in.

cause the settler unit to become unreasonably small.

vt = terminal settling velocity, in./min

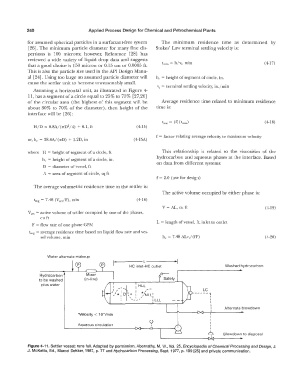

Assuming a horizontal unit, as illustrated in Figure 4-

11, has a segment ofa circle equal to 25% to 75% [27,26]

of the circular area (the highest of this segment will be Average residence time related to minimum residence

about 30% to 70% of the diameter), then height of the time is:

interface will be [26]:

( 4-18)

H/D = 0.8A/(7iD 2 /4) + 0.1, ft (4-15)

f = factor relating average velocity to maximum velocity

or, he = 38.4A/ ( TID) + l.20, in (4-15A)

where H = height of segment of a circle, fl This relationship is related to the viscosities of the

hydrocarbon and aqueous phases at the interface. Based

he = height of segment of a circle, in.

on data from different systems:

D = diameter of vessel, ft

A = area of segment of circle, sq ft

f = 2.0 (use for design)

The average volumetric residence time in the settler is:

The active volume occupied by either phase is:

la,g = 7.48 (VseJF), min ( 4-16)

V = AL, cu ft ( 4-19)

Vw = active volume of settler occupied by one of the phases,

cu ft

L = length of vessel, ft, inlet to outlet

F = flow rate of one phase GPM

lavg = average residence time based on liquid flow rate and ves-

sel volume, min he = 7.48 ALvJ (ff) ( 4-20)

Water alternate makeup

------L------

.. HC inlet-HG outlet Washed hydrocarbon

Hydrocarbon Mixer <}--

to be washed (in-line) Safety

plus water

LC

-----,

I

I

I

i

I Alternate blowdown

*Velocity< 10"/min

Q

Aqueous circulation I

Blowdown to disposal

Figure 4-11. Settler vessel; runs full. Adapted by permission, Abernathy, M. W., Vol. 25, Encyclopedia of Chemical Processing and Design, J.

J. McKetta, Ed., Marcel Dekker, 1987, p. 77 and Hydrocarbon Processing, Sept.1977, p.199 [25] and private communication.