Page 300 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 300

270 Applied Process Design for Chemical and Petrochemical Plants

GAi INLET

CLEAN AIR OUTLET

t

1 1 I 1

SUPPLEMENTARY INSPECTION

WATER INLET�� --DOOR

INSPECTION

WASHING --oooR

LIQUID INLET

INSPECTION

--oooR

BOX

VANES

INSPECTION

DCOR -

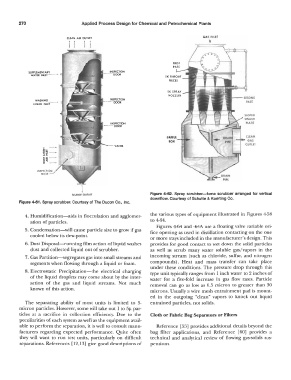

Figure 4-62. Spray scrubber-fume scrubber arranged for vertical

SLUDGE OUTLET

downflow. Courtesy of Schutte & Koerting Co.

Figure 4-61. Spray scrubber. Courtesy of The Ducon Co., Inc.

4. Humidification-aids in flocculation and agglomer- the various types of equipment illustrated in Figures 4-58

ation of particles. to 4-64.

Figures 4-64 and -64A use a floating valve variable ori-

5. Condensation-will cause particle size to grow if gas fice opening as used in distillation contacting on the one

cooled below its dew-point.

or more trays included in the manufacturer's design. This

6. Dust Disposal-running film action of liquid washes provides for good contact to wet down the solid particles

dust and collected liquid out of scrubber. as well as scrub many water soluble gas/vapors in the

7. Gas Partition-segregates gas into small streams and incoming stream (such as chloride, sulfur, and nitrogen

segments when flowing through a liquid or foam. compounds). Heat and mass transfer can take place

under these conditions. The pressure drop through this

8. Electrostatic Precipitation-the electrical charging type unit typically ranges from 1 inch water to 2 inches of

of the liquid droplets may come about by the inter- water for a five-fold increase in gas flow rates. Particle

action of the gas and liquid streams. Not much removal can go as low as 0.5 micron to greater than 30

known of this action. microns. Usually a wire mesh entrainment pad is mount-

ed in the outgoing "clean" vapors to knock out liquid

The separating ability of most units is limited to 5- entrained particles, not solids.

micron particles. However, some will take out 1 to 5µ par-

ticles at a sacrifice in collection efficiency. Due to the Cloth or Fabric Bag Separators or Filters

peculiarities of each system as well as the equipment avail-

able to perform the separation, it is well to consult manu- Reference [55] provides additional details beyond the

facturers regarding expected performance. Quite often bag filter applications, and Reference [60] provides a

they will want to run test units, particularly on difficult technical and analytical review of flowing gas-solids sus-

separations. References [12,13] give good descriptions of pensions.