Page 302 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 302

272 Applied Process Design for Chemical and Petrochemical Plants

LIQUID LI.V£L

D'- Clean gas out

LDW PIU!SSURE

l)flOP V£NTURI ___..#// FLEXITRAV

�

li.NTllY ,J � q9

1

Figure 4-64A. Adjustable "floating" caps for vapor flow. By permis-

sion, Koch Engineering Co., Inc.

Gas plus

suspended

solids In

+A>

�

DUST

STORAGE

HOPPER

FILTERING CLEAN I NG

The scrubber is comprised of one or more trays. Each tray contains

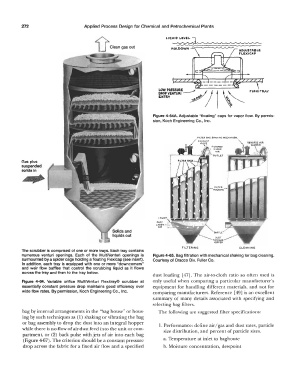

numerous venturi openings. Each of the MultiVenturi openings is Figure 4-65. Bag filtration with mechanical shaking for bag cleaning.

surmounted by a spider cage holding a floating Flexicap (see insert). Courtesy of Dracco Div. Fuller Co.

In addition, each tray Is equipped with one or more "downcomers"

and weir flow baffles that control the scrubbing liquid as it flows

across the tray and then to the tray below.

dust loading [ 47]. The air-to-cloth ratio so often used is

Figure 4-64. Variable orifice MultiVenturi Flexitray® scrubber at only useful when comparing a particular manufacturer's

essentially constant pressure drop maintains good efficiency over equipment for handling different materials, and not for

wide flow rates. By permission, Koch Engineering Co., Inc. comparing manufacturers. Reference [ 49] is an excellent

summary of many details associated with specifying and

selecting bag filters.

bag by internal arrangements in the "bag house" or hous- The following are suggested filter specifications:

ing by such techniques as (1) shaking or vibrating the bag

or bag assembly to drop the dust into an integral hopper l. Performance: define air /gas and dust rates, particle

while there is no-flow of air-dust feed into the unit or com- size distribution, and percent of particle sizes.

partment, or (2) back pulse with jets of air in to each bag

(Figure 4-67). The criterion should be a constant pressure a. Temperature at inlet to baghouse

drop across the fabric for a fixed air flow and a specified b. Moisture concentration, dewpoint