Page 421 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 421

388 Applied Process Design for Chemical and Petrochemical Plants

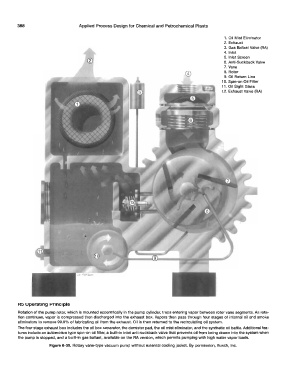

1. Oil Mist Eliminator

2. Exhaust

3. Gas Ballast Valve (RA)

4. Inlet

5. Inlet Screen

® 6. Anti-Suckback Valve

7. Vane

8. Rotor

9. Oil Return Line

10. Spin-on Oil Filter

11. Oil Sight Glass

12. Exhaust Valve (RA)

R5 uperatmg Prmc1p1e

Rotation of the pump rotor, which is mounted eccentrically in the pump cylinder, traps entering vapor between rotor vane segments. As rota-

tion continues, vapor is compressed then discharged into the exhaust box. Vapors then pass through four stages of internal oil and smoke

eliminators to remove 99.9% of lubricating oil from the exhaust. Oil is then returned to the recirculating oil system.

The four stage exhaust box includes the oil box separator, the demister pad, the oil mist eliminator, and the synthetic oil baffle. Additional fea-

tures include an automotive type spin-on oil filter, a built-in inlet anti-suckback valve that prevents oil from being drawn into the system when

the pump is stopped, and a built-in gas ballast, available on the RA version, which permits pumping with high water vapor loads.

Figure 6-39. Rotary vane-type vacuum pump without external cooling jacket. By permission, Busch, Inc.