Page 417 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 417

Ejectors and Mechanical Vacuum Systems 385

8,000

:E I

:::, CONDENSATION BONUS

:::, -

� 904-R2 at 240 rpm 70of SEAL

;::i

� 7,000 I OF sA.i. ""poR

<( 20

1 VAPOR 70°F SEAL

� 1100F SAT.

LL. 60oFSEA

0 aooF SAT. VAPOR �

> .. ---

1- 6,000 -........_

� - 60°F DRY AIR 60oF SEAL

0:

<)

I I I I I I I I I I I

15 20 24

VACUUM, INCHES OF MERCURY

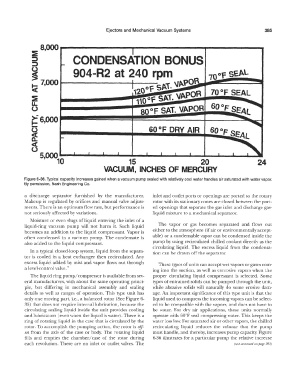

Figure 6-36. Typical capacity increases gained when a vacuum pump sealed with relatively cool water handles air saturated with water vapor.

By permission, Nash Engineering Co.

a discharge separator furnished by the manufacturer. inlet and outlet ports or openings are ported so the rotary

Makeup is regulated by orifices and manual valve adjust- rotor with its stationary cones are closed between the port-

ments. There is an optimum flow rate, but performance is ed openings that separate the gas inlet and discharge gas-

not seriously affected by variations. liquid mixture to a mechanical separator.

Moisture or even slugs of liquid entering the inlet of a

liquid-ring vacuum pump will not harm it. Such liquid The vapor or gas becomes separated and flows out

becomes an addition to the liquid cornpressanl. Vapor is either to the atmosphere (if air or environmentally accept-

often condensed in a vacuum pump. The condensate is able) or a condensable vapor can be condensed inside the

also added to the liquid cornpressant. pump by using recirculated chilled coolant directly as the

circulating liquid. The excess liquid from the condensa-

In a typical closed-loop system, liquid from the separa- tion can be drawn off the separator.

tor is cooled in a heat exchanger then recirculated. Any

excess liquid. added by mist and vapor flows out through These types of units can accept wet vapors or gases com-

a level-control valve."

ing into the suction, as well as corrosive vapors when the

The liquid ring pump/compressor is available from sev- proper circulating liquid compressan t is selected. Some

eral manufacturers, with about the same operating princi- types of entrained solids can be pumped through the unit,

ple, but differing in mechanical assembly and sealing while abrasive solids will naturally do some erosive dam-

details as well as ranges of operation. This type unit has age. An important significance of this type unit is that the

only one moving part, i.e., a balanced rotor (See Figure 6- liquid used to compress the incoming vapors can be select-

35) that does not require internal lubrication, because the ed to be compatible with the vapors, and does not have to

circulating sealing liquid inside the unit provides cooling be water. For dry air applications, these units normally

and lubrication (even when the liquid is water). There is a operate with 60°F seal compressing water. This keeps the

ring of rotating liquid in the case that is circulated by the waler loss low. For saturated air or other vapors, the chilled

rotor. To accomplish the pumping action, the rotor is off recirculating liquid reduces the volume that the pump

set from the axis of the case or body. The rotating liquid must handle, and thereby, increases pump capacity. Figure

fills and empties the chamber/case of the rotor during 6-36 illustrates for a particular pump the relative increase

each revolution. There are no inlet or outlet valves. The (text continued Dtl page 393)