Page 416 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 416

384 Applied Process Design for Chemical and Petrochemical Plants

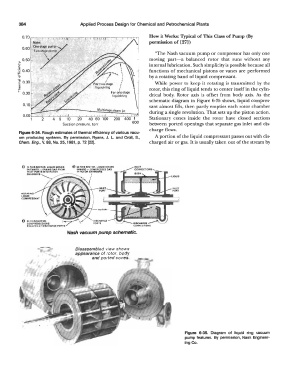

How it Works: Typical of This Class of Pump (By

permission of [27])

0.60

'The Nash vacuum pump or compressor has only one

> 0.50 moving part-a balanced rotor that runs without any

o internal lubrication. Such simplicity is possible because all

c

"'

� 0.40 functions of mechanical pistons or vanes are performed

by a rotating band of liquid compressant.

Q)

§ 0.30 ' I While power to keep it rotating is transmitted by the

Q)

s: ' I rotor, this ring of liquid tends to center itself in the cylin-

f- 0.20 For one-stage drical body. Rotor axis is offset from body axis. As the

liquid-ring

schematic diagram in Figure 6-35 shows, liquid cornpres-

0.10 sant almost fills, then partly empties each rotor chamber

Multistage steam jet

during a single revolution. That sets up the piston action.

Stationary cones inside the rotor have closed sections

Suction pressure, torr between ported openings that separate gas inlet and dis-

charge flows.

Figure 6-34. Rough estimates of thermal efficiency of various vacu-

um producing systems. By permission, Ryans, J. L. and Croll, S., A portion of the liquid compressant passes out with dis-

Chem. Eng., V. 88, No. 25, 1981, p. 72 [22]. charged air or gas. It is usually taken out of the stream by

O IN THIS secroa LIQUID MOVES

OUTWARD - DRAWS GAS FROM

INl.El PORlS INTO ROTOR

CHAM8EAS

LIOUID

Nash vacuum pump schematic.

Disassembled view shows

appearance of rotor, body

and ported cones.

Figure 6-35. Diagram of liquid ring vacuum

pump features. By permission, Nash Engineer-

ing Co.