Page 120 - Module DMV20173

P. 120

6.0 POLYMER PROCESSING

7.3 POLYMER EXTRUSION

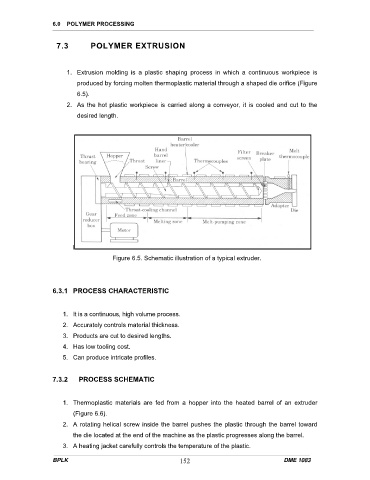

1. Extrusion molding is a plastic shaping process in which a continuous workpiece is

produced by forcing molten thermoplastic material through a shaped die orifice (Figure

6.5).

2. As the hot plastic workpiece is carried along a conveyor, it is cooled and cut to the

desired length.

l

Figure 6.5. Schematic illustration of a typical extruder.

6.3.1 PROCESS CHARACTERISTIC

1. It is a continuous, high volume process.

2. Accurately controls material thickness.

3. Products are cut to desired lengths.

4. Has low tooling cost.

5. Can produce intricate profiles.

7.3.2 PROCESS SCHEMATIC

1. Thermoplastic materials are fed from a hopper into the heated barrel of an extruder

(Figure 6.6).

2. A rotating helical screw inside the barrel pushes the plastic through the barrel toward

the die located at the end of the machine as the plastic progresses along the barrel.

3. A heating jacket carefully controls the temperature of the plastic.

BPLK 152 DME 1083