Page 138 - Module DMV20173

P. 138

7.0 NON CONVENTIONAL PROCESSES

7.3 WIRE ELECTRICAL DISCHARGE MACHINING (WIRE EDM)

1. Electrical discharge wire cutting or also known as wire EDM is a process of

producing complex two and three dimensional shapes using a simple wire

eroding the material from an electrically conducting material.

2. This process is used to cut plates as thick as 300 mm and to make punches,

tools and dies from hard metals.

3. It also can ut intricate components for the electronics industry.

4. The cutting action in wire EDM is achieved by thermal energy from electric

discharges between the electrode wire and the workpiece.

5. The wire moves past the workpiece at fast rates up to 3 m/min.

6. The spark is struck between the moving electrode wire and the workpiece,

thereby removing the material.

7. A constant gap or kerf is maintained during the cut.

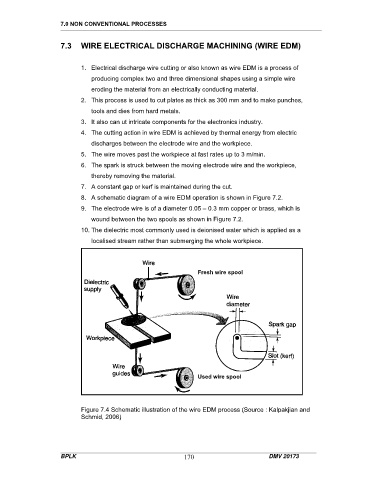

8. A schematic diagram of a wire EDM operation is shown in Figure 7.2.

9. The electrode wire is of a diameter 0.05 – 0.3 mm copper or brass, which is

wound between the two spools as shown in Figure 7.2.

10. The dielectric most commonly used is deionised water which is applied as a

localised stream rather than submerging the whole workpiece.

Fresh wire spool

Used wire spool

Figure 7.4 Schematic illustration of the wire EDM process (Source : Kalpakjian and

Schmid, 2006)

BPLK 170 DMV 20173