Page 135 - Module DMV20173

P. 135

7.0 NON CONVENTIONAL PROCESSES

7. The flowing dielectric then flushed away the small particles.

8. The amount of metal removed per spark depends upon the electrical energy

expended per spark and the period over which it is expended.

9. Two important process parameters in EDM are discharge current and frequency

discharges.

10. As either of these parameters is increased, metal removal rate and surface

roughness increases.

11. Since the process does not involve mechanical energy, the hardness, strength,

and toughness of the workpiece material do not necessarily influence the removal

rate.

12. The melting point and the latent heat of melting are important physical properties

that determine the volume of metal removed per discharge.

13. The material removal rate (MRR) can be related to melting point approximately

by the following empirical formula (Kalpakjian et. al. 2006):

MRR = 4 x 10 ITw -1.23 (8.1)

4

where MRR is in mm3/min, I is the current in amperes, and Tw is the melting point

of the workpiece in °C.

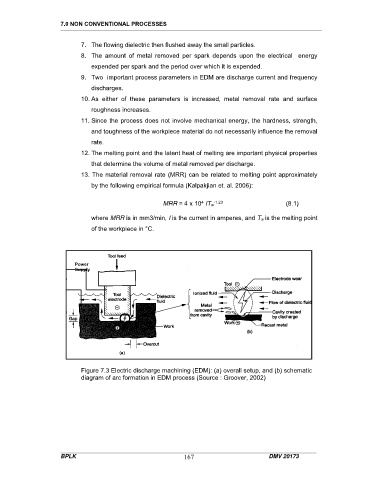

Power

Supply

Figure 7.3 Electric discharge machining (EDM): (a) overall setup, and (b) schematic

diagram of arc formation in EDM process (Source : Groover, 2002)

BPLK 167 DMV 20173