Page 14 - Module DMV20173

P. 14

2.0 CASTING PROCESSES

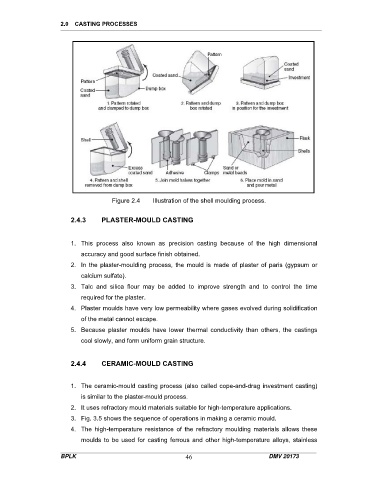

Figure 2.4 Illustration of the shell moulding process.

2.4.3 PLASTER-MOULD CASTING

1. This process also known as precision casting because of the high dimensional

accuracy and good surface finish obtained.

2. In the plaster-moulding process, the mould is made of plaster of paris (gypsum or

calcium sulfate).

3. Talc and silica flour may be added to improve strength and to control the time

required for the plaster.

4. Plaster moulds have very low permeability where gases evolved during solidification

of the metal cannot escape.

5. Because plaster moulds have lower thermal conductivity than others, the castings

cool slowly, and form uniform grain structure.

2.4.4 CERAMIC-MOULD CASTING

1. The ceramic-mould casting process (also called cope-and-drag investment casting)

is similar to the plaster-mould process.

2. It uses refractory mould materials suitable for high-temperature applications.

3. Fig. 3.5 shows the sequence of operations in making a ceramic mould.

4. The high-temperature resistance of the refractory moulding materials allows these

moulds to be used for casting ferrous and other high-temperature alloys, stainless

BPLK 46 DMV 20173