Page 15 - Module DMV20173

P. 15

2.0 CASTING PROCESSES

steels, and tool steels.

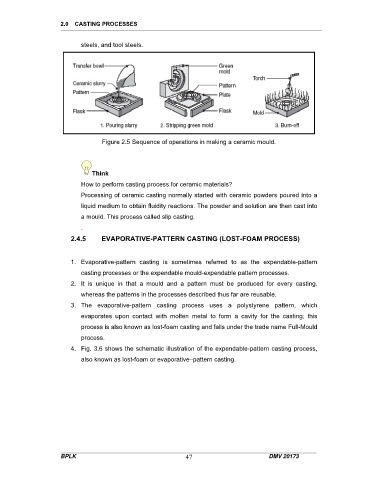

Figure 2.5 Sequence of operations in making a ceramic mould.

Think

How to perform casting process for ceramic materials?

Processing of ceramic casting normally started with ceramic powders poured into a

liquid medium to obtain fluidity reactions. The powder and solution are then cast into

a mould. This process called slip casting.

.

2.4.5 EVAPORATIVE-PATTERN CASTING (LOST-FOAM PROCESS)

1. Evaporative-pattern casting is sometimes referred to as the expendable-pattern

casting processes or the expendable mould-expendable pattern processes.

2. It is unique in that a mould and a pattern must be produced for every casting,

whereas the patterns in the processes described thus far are reusable.

3. The evaporative-pattern casting process uses a polystyrene pattern, which

evaporates upon contact with molten metal to form a cavity for the casting; this

process is also known as lost-foam casting and falls under the trade name Full-Mould

process.

4. Fig. 3.6 shows the schematic illustration of the expendable-pattern casting process,

also known as lost-foam or evaporative–pattern casting.

BPLK 47 DMV 20173