Page 26 - Module DMV20173

P. 26

2.0 CASTING PROCESSES

2.6 COMPOSITE MOULDS CASTING

1. Composite moulds are made of two or more different materials (such as sand,

graphite, and metal) combining the advantages of each material.

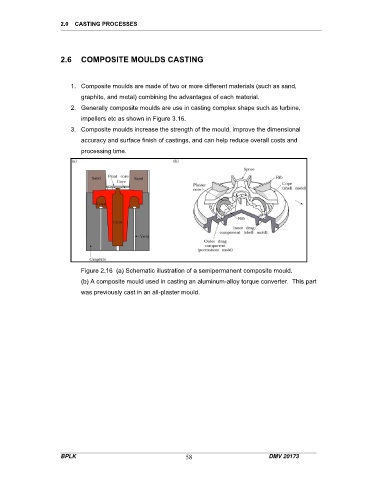

2. Generally composite moulds are use in casting complex shape such as turbine,

impellers etc as shown in Figure 3.16.

3. Composite moulds increase the strength of the mould, improve the dimensional

accuracy and surface finish of castings, and can help reduce overall costs and

processing time.

Figure 2.16 (a) Schematic illustration of a semipermanent composite mould.

(b) A composite mould used in casting an aluminum-alloy torque converter. This part

was previously cast in an all-plaster mould.

BPLK 58 DMV 20173