Page 21 - Module DMV20173

P. 21

2.0 CASTING PROCESSES

2.5.4 DIE CASTING

1. The die casting process is a further example of permanent-mould casting.

2. Typical parts made by die casting are motor housings, engine blocks, business-

machine and appliance components, hand tools, and toys.

3. In this process, the molten metal is forced into the die cavity at high pressures.

4. Die casting has the capability for rapid production of strong, high-quality parts with

complex shapes, especially with aluminum, brass, magnesium, and zinc.

5. These machines are large compared to the size of the casting, because high forces

are required to keep the two halves of the dies closed under pressure.

6. It also produces good dimensional accuracy and surface details, so that parts require

little or no subsequent machining or finishing operations (net-shape forming).

7. There are two basic types of die-casting machines:

a) Hot-chamber die-casting.

b) Cold-chamber die-casting.

2.5.5 HOT-CHAMBER DIE-CASTING

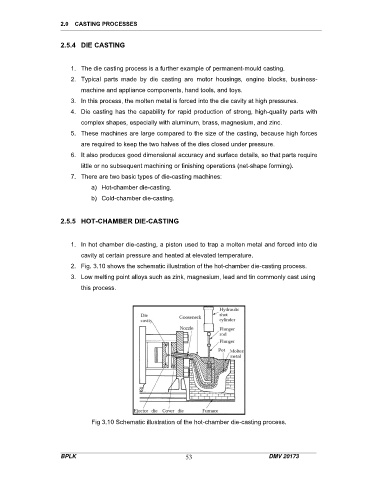

1. In hot chamber die-casting, a piston used to trap a molten metal and forced into die

cavity at certain pressure and heated at elevated temperature.

2. Fig. 3.10 shows the schematic illustration of the hot-chamber die-casting process.

3. Low melting point alloys such as zink, magnesium, lead and tin commonly cast using

this process.

Fig 3.10 Schematic illustration of the hot-chamber die-casting process.

BPLK 53 DMV 20173